Color Difference Detection: A Key Technology in Coating Quality Control

Color difference detection is an important method to ensure color consistency in coatings. It utilizes different tools and methods to identify discrepancies between a sample and standard colors, ensuring that each batch of coating meets the expected color. Color difference detection is widely used in coating production, coating application, and final product quality inspection.

I. Importance of Color Difference Detection:

Improving Coating Quality: Color difference detection allows timely detection and correction of color issues, improving the overall quality of coatings and preventing non-conforming coatings from affecting the final result.

Ensuring Color Consistency: Color difference detection ensures that coatings from different batches and production processes maintain color consistency, avoiding discrepancies that may affect the coating appearance.

II. Methods of Color Difference Detection:

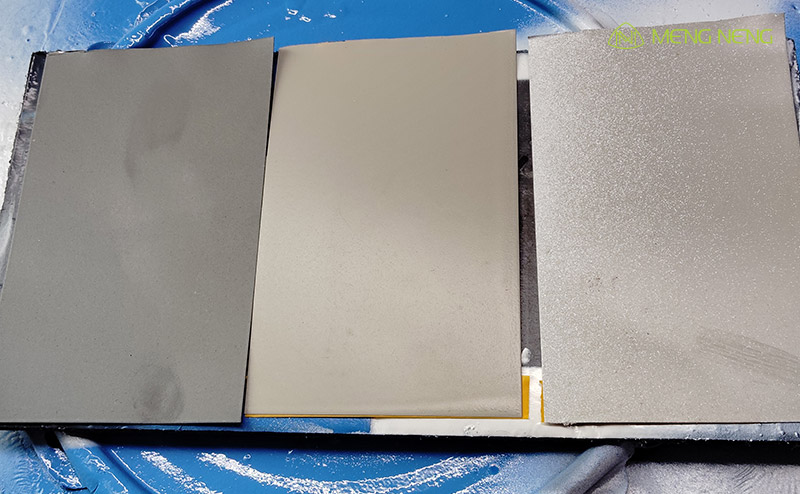

Visual Inspection: A visual comparison between the sample and standard colors to assess if there is any color difference. This method is simple but influenced by environmental factors like lighting.

Instrumental Detection: Using instruments such as colorimeters, this method quantitatively measures color differences. It is more precise and provides digital color difference data.

III. Factors Affecting Color Difference:

Coating Formulation: Different coating formulations and pigments may result in slight color variations.

Application Environment: Environmental factors such as temperature, humidity, and lighting may affect the appearance of the coating color.

IV. Conclusion:

Color difference detection is an essential step in ensuring coating quality. By using appropriate methods to detect and correct color discrepancies, the overall appearance of coatings can be significantly improved, ensuring color consistency in the final application.