Marine Photovoltaic Anti-Corrosion Solve

The marine environment poses multiple corrosion threats to photovoltaic facilities: the high concentration of salts and chloride ions in seawater accelerates the electrochemical corrosion process of metal materials. Salt mist, humid air, and UV radiation in the ocean can damage the surface coatings of photovoltaic brackets and modules, leading to failure of the protective layer. Additionally, the attachment of marine organisms such as algae and shellfish not only increases the weight of the photovoltaic facilities but also adds extra corrosion pressure. Therefore, to ensure the long-term stable operation of photovoltaic systems, corrosion-resistant coatings such as galvanizing and graphene composite coating technologies should be applied to the surface of photovoltaic brackets, with a protective lifespan exceeding 25 years.

-

Corrosion Background

Corrosion Background -

Design Basis

Design Basis -

Offshore Photovoltaic Overall Solution

Offshore Photovoltaic Overall Solution -

Steel Structure Platforms

Steel Structure Platforms -

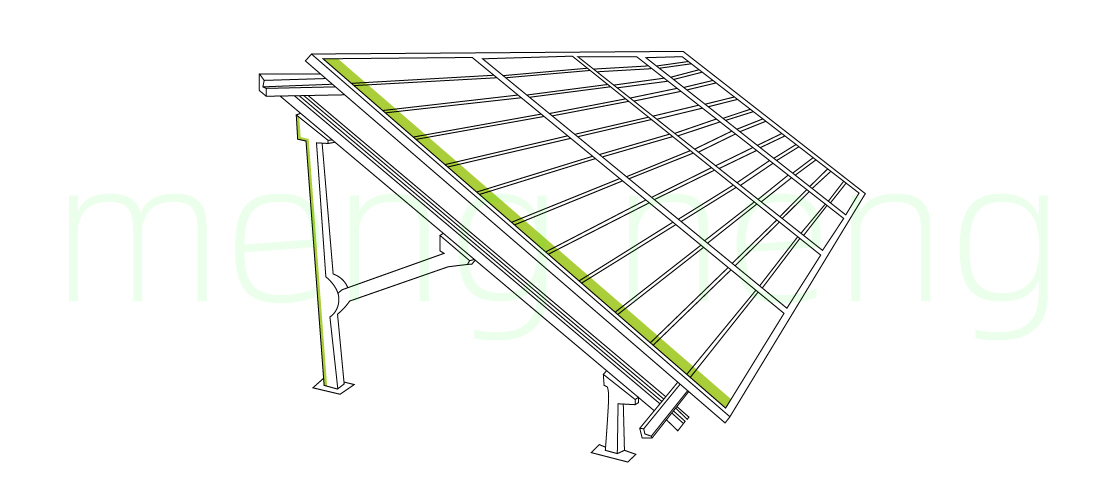

Photovoltaic Support System

Photovoltaic Support System -

Boosting Station Anti-corrosion

Boosting Station Anti-corrosion -

Installation and Daily Operation

Installation and Daily Operation

-

- Marine Photovoltaic Background

-

Offshore photovoltaics refer to photovoltaic power generation systems built in marine environments. These photovoltaic power stations are typically installed on floating platforms, which can be either fixed or capable of floating with the changing water levels. Offshore photovoltaic power stations can be divided into two main types: nearshore (coastal) photovoltaics and farshore photovoltaics.

I. Advantages of Developing Offshore Photovoltaics in China

China has several advantages in developing offshore photovoltaics, mainly in the following aspects:

1. Rich Solar Energy Resources: Coastal areas in China receive long durations of sunlight, providing abundant solar resources for offshore photovoltaic power stations.

2. Vast Construction Space: With over 18,000 kilometers of coastline and vast nearshore waters, there is ample space for offshore photovoltaic power stations. Marine space is not restricted by land resources, allowing for large-scale deployment of photovoltaic stations and efficient use of spatial resources.

3. High Power Generation Efficiency: The sea surface is free from obstructions, with long durations of sunlight, resulting in high efficiency. Typically, offshore photovoltaic projects generate 5%-10% more power than land-based ones. The natural cooling effect of the sea surface helps reduce the working temperature of photovoltaic modules, thus enhancing power generation efficiency.

4. Local Power Consumption Advantage: Coastal areas tend to be densely populated with high levels of economic development, resulting in a large demand for electricity. Therefore, the electricity generated by offshore photovoltaic stations can be directly supplied to local areas, reducing transmission losses.

5. Shorter Construction Period: Compared to traditional energy projects, offshore photovoltaic power stations have shorter construction periods and can be put into operation more quickly.

6. Water Conservation: Unlike traditional thermal power plants, offshore photovoltaic stations do not consume large amounts of water, which helps alleviate water resource pressure.

7. Reduced Land Use: Offshore photovoltaic stations avoid occupying valuable land resources, which is particularly important in regions with scarce land.

8. Diverse Application Scenarios: Offshore photovoltaic power stations can be constructed independently or integrated with other industries such as marine fisheries, seawater desalination, and marine tourism, achieving multiple functions.

9. Policy Support: Government policies supporting clean energy provide guarantees and financial subsidies for offshore photovoltaic projects.

10. Technological Innovation and Cost Reduction: With advancements in technology and the scaling effect, the cost of offshore photovoltaics is gradually decreasing, making it more attractive for investors.

11. Addressing Climate Change: The development of offshore photovoltaics helps reduce greenhouse gas emissions, which is crucial for achieving the "dual carbon" goals (carbon peak and carbon neutrality).

In conclusion, China has clear geographical and resource advantages for developing offshore photovoltaics. Combined with government support and technological advancements, the offshore photovoltaic industry is poised to become an important force in promoting clean energy development.

II. Major Corrosion Challenges Facing Offshore Photovoltaics

Offshore photovoltaics face various corrosion threats, mainly due to the special nature of the marine environment. The following are the main types of corrosion encountered by offshore photovoltaics:

Seawater Corrosion: Seawater is a complex electrolyte solution containing high concentrations of salts, dissolved gases (such as oxygen and carbon dioxide), and microorganisms. These factors can lead to electrochemical reactions on metal surfaces, causing corrosion.

Marine Microbial Corrosion: Marine microorganisms (such as sulfate-reducing bacteria) produce acidic substances during their metabolism, which can chemically react with metal surfaces, leading to severe corrosion.

Fatigue Corrosion: Wind turbines undergo periodic mechanical load changes during operation. These dynamic loads cause microcracks in metal materials, which, over time, expand and eventually lead to metal fatigue failure.

Stress Corrosion Cracking: This type of corrosion occurs when metals are subjected to tensile stress in a specific corrosive environment, causing cracking. Offshore photovoltaic equipment is subjected to various stresses during operation, and the combination of these stresses with corrosive agents leads to stress corrosion cracking.

Biofouling Corrosion: Marine organisms (such as mollusks and algae) attach to parts of the wind turbines, and their life activities and the remains left behind after their death accelerate material corrosion.

Atmospheric Corrosion: For non-submerged parts of offshore photovoltaic equipment, high humidity, strong salt mist, and intense sunlight can cause atmospheric corrosion of metal components.

III. Mengneng Coatings Experts’ Strategy to Tackle Corrosion

To address these corrosion issues, offshore photovoltaic systems have adopted a series of measures:

Use of Corrosion-Resistant Materials: Materials such as stainless steel, aluminum alloys, or special steel (e.g., magnesium-aluminum-zinc-coated steel plates) are used for photovoltaic frames and other metal components.

Surface Treatment Technology: Surface treatment technologies such as hot-dip galvanizing and aluminum-magnesium-zinc coating are used to enhance the corrosion resistance of metal parts.

Special Coatings: Graphene-based heavy-duty anti-corrosion coatings, such as graphene epoxy zinc primer and polyurethane coatings, are applied to metal components.

Cathodic Protection: Sacrificial anodes or impressed current methods are used to provide cathodic protection, preventing metal components from corroding.

Regular Maintenance: Regular inspections and maintenance of photovoltaic modules and their supports are carried out, including cleaning biological attachments and repairing damaged anti-corrosion layers.

Through these measures, we can effectively reduce corrosion issues in offshore photovoltaic systems, enhancing system reliability and extending service life.

-

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience