Mining Equipment Anti-Corrosion Solve

The quality of mining machinery and equipment has a significant impact on the normal operation of coal mining work and is also an effective guarantee for the safety of on-site construction personnel. However, due to environmental factors and inadequate daily maintenance and management, mining machinery and equipment often suffer from wear and corrosion, causing the original functions of the equipment to fail. Although the corrosion process of metals is slow, the damage it causes is considerable, as it disrupts the normal operation of mining machinery, reduces its service life, and even leads to equipment scrapping. This is a widespread and serious issue.

-

Corrosion Background

Corrosion Background -

Design Basis

Design Basis -

Belt Conveyors

Belt Conveyors -

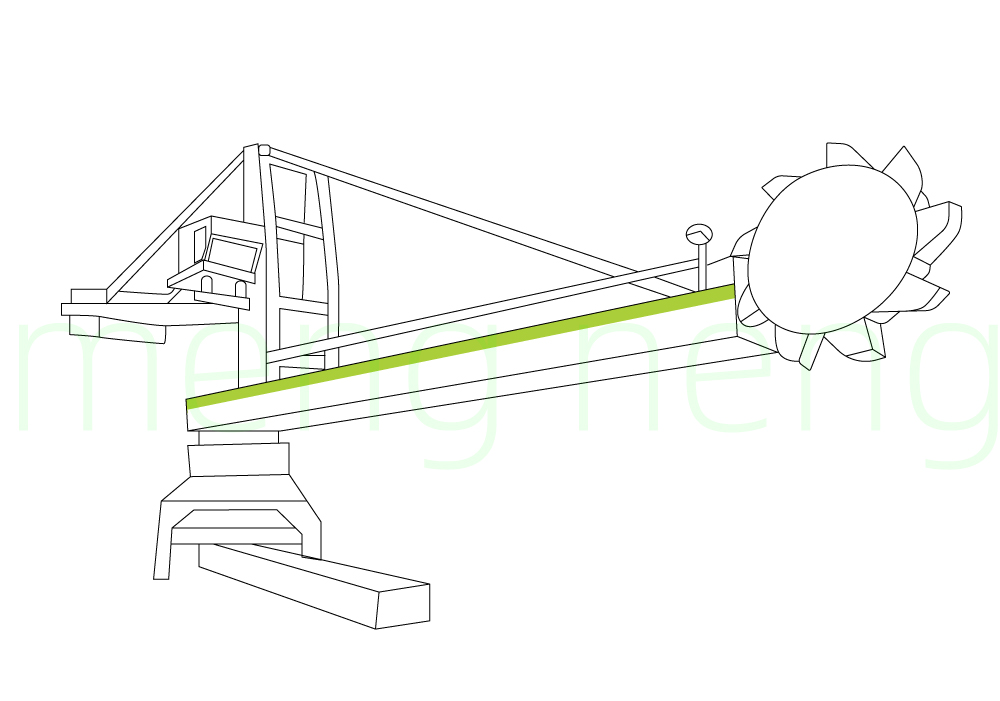

Bucket Wheel Excavators

Bucket Wheel Excavators -

Crushers

Crushers -

Ore Dressing Machines

Ore Dressing Machines -

Dust Collectors

Dust Collectors

-

- Corrosion Background

-

1. Corrosion Background of Mining Equipment

Corrosion refers to the damage or deterioration of mining equipment caused by the surrounding environment. Broadly, corrosion includes all forms of material degradation beyond simple mechanical damage, and the objects of corrosion encompass various materials. Conventionally, "corrosion" is used to describe the degradation of metallic materials, while the corrosion of non-metallic materials has a separate term. Mining equipment corrosion generally refers to the damage or deterioration of equipment materials caused by the chemical or electrochemical effects of the surrounding medium, or by the combined action of mechanical, biological, and other factors.

At high temperatures, or in dry atmospheres, corrosion occurs when the surface of mining equipment directly reacts with acidic gases such as oxygen, chlorine, hydrogen sulfide, sulfur dioxide, or with other non-dissolving substances. The chemical reactions lead to the corrosion of the metal, which is referred to as "chemical corrosion." In humid atmospheres, or in water and other dissolving solutions, due to the non-homogeneity of the metal composition and structure of mining equipment surfaces, or due to differences in medium concentration, temperature, and other factors, many tiny chemical cells are formed on the metal surface. The action of these cells leads to electrochemical reactions that result in metal corrosion, which is called "electrochemical corrosion."

-

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience