How to Repair?

Common coating problems include bubbling, cracking, peeling, and color differences. Bubbling may occur due to high humidity or rapid drying; cracking is usually caused by excessive coating thickness or substrate mismatch; peeling is often due to improper surface preparation or poor adhesion; and color differences may arise from uneven mixing of the coating. To prevent these issues, control of temperature and humidity in the application environment is essential, ensuring surface cleanliness and choosing the appropriate coating. For problems that have already occurred, they can be resolved by sanding, re-coating, or replacing the coating, ensuring that the coating performance meets the standards.

-

-

Nineteen Types of Coating Defects and Their Repairs

During the coating process, defects are inevitable, especially when using spraying methods, which require high skill. Inexperienced painters find it difficult to avoid coating defects. Some defects occur during the curing and drying of the coating, while others appear only after the coating is put into use.

Poor coating procedures can lead to various problems. If the equipment is inappropriate, poorly maintained, or the personnel lack skills, coating defects are likely to occur. Experienced workers can avoid some issues, but some defects are unavoidable. In addition to weather conditions, which have a significant impact on the final result, it is important to understand other conditions that may lead to coating defects, so we can effectively prevent them.

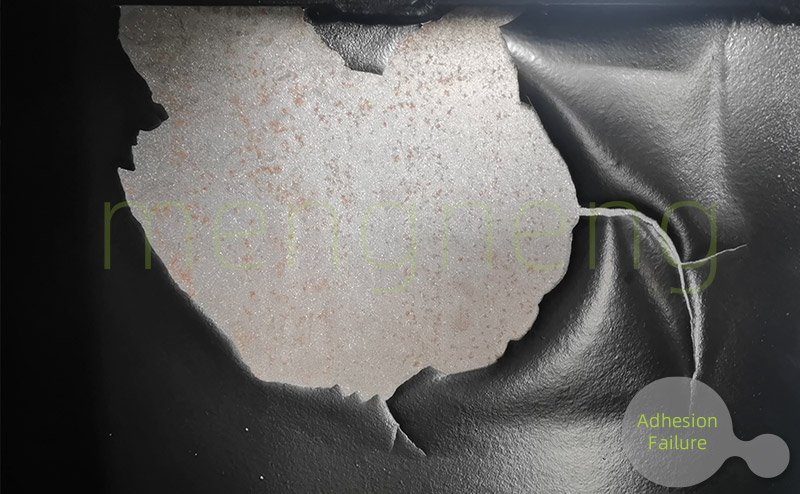

- 1. Adhesion Failure/Detachment/Peeling Off

-

Loss of adhesion between the coating and substrate or between two coatings.

Possible Causes:

Surface contamination or condensation.

Prevention:

1. Ensure the surface is clean, dry, and free of contaminants;

2. Proper surface preparation;

3. Apply the correct system as per instructions.Repair:

Remove the defect based on its extent, perform appropriate surface preparation, and use the correct coating system as recommended by the manufacturer.

- 2. Dry Spray

-

Rough and uneven surface finish due to insufficient flow of particles, resulting in poor adhesion.

Possible Causes:

1. Incorrect spraying technique, e.g., incorrect gun distance;

2. Fast-drying products (solvent evaporates too quickly);

3. High temperature during application;

4. Strong winds during spraying.Prevention:

1. Use proper equipment and spraying technique;

2. Use slower drying solvents;

3. Spray in appropriate environmental conditions;

4. Follow recommended procedures.Repair:

Before curing or drying: Use a dry brush to remove overspray and wipe with solvent; After curing or drying: Sand and reapply the coating.

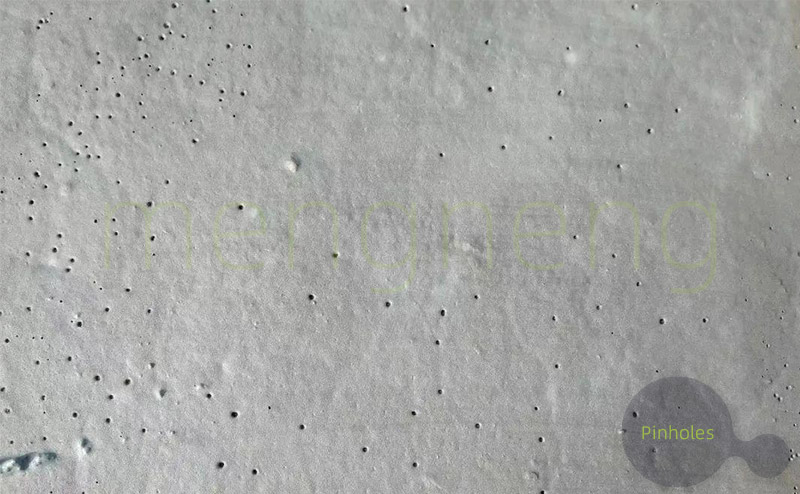

- 3. Pinholes

-

Small, deep holes caused by air or solvent gas trapped in the coating during application and drying, leading to pitting before the coating has dried.

Possible Causes:

1. Trapped solvent or air in the coating;

2. Coating applied over porous surfaces like inorganic zinc coatings or metal spray surfaces, which are particularly prone to pinholes;

3. Incorrect spraying techniques and improper solvent use.Prevention:

1. Apply proper procedures and select the appropriate coating system;

2. Use suitable solvents and work in good environmental conditions;

3. Check spraying equipment and maintain appropriate gun distance.Repair:

Sand, clean, and apply the appropriate primer/intermediate coat and topcoat.

- 4. Runs & Sags/Curtains

-

Runs: When the coating is too thick, it moves downward or drips like tears, forming a waterfall-like effect.

Possible Causes:

1. Coating too thick;

2. Excessive solvent;

3. Incorrect (or lack of) hardener or unskilled application;

4. Extreme environmental conditions (too cold or too hot).Prevention:

Use the correct coating system, apply proper procedures, and choose the correct dry film thickness.

Repair:

1. Remove the runs while the coating is still wet using a brush or roller;

2. Once dry, sand the defective surface and recoat or touch up as necessary. - 5. Bleaching/Fading

-

Bleaching/Fading: Partial or complete loss of the original color of the coating.

Possible Causes:

Bleaching: Due to exposure to the atmosphere or chemical attacks;

Fading: Due to exposure to the atmosphere and ultraviolet rays.Prevention:

Use pigments with good color stability/UV resistance or coatings resistant to chemical environments.

Repair:

Remove the faded coating, or sand and re-coat with a more appropriate coating system.

- 6. Chalking

-

Chalking: A layer of friable powder on the surface of the coating, which can also cause discoloration or fading of the coating. The rate of chalking varies depending on the pigment concentration and resin type chosen. Chalking is a characteristic of some coatings, such as epoxy coatings.

Possible Causes:

Exposure to the atmosphere and/or ultraviolet rays, causing resin degradation in the coating.

Prevention:

Use an appropriate topcoat that is resistant to chalking and ultraviolet rays.

Repair:

Remove all chalked material and loose particles through sanding or light sanding, and re-coat with a chalk-resistant topcoat.

- 7. Bleeding/Bleed-through

-

Bleeding: The diffusion process where colored substances from the lower substrate or film penetrate and pass through the top layer of the film, causing unwanted discoloration or change in the coating’s color.

Possible Causes:

Diffusion of soluble colored substances from the underlying layer of coating to the surface of subsequent layers, causing loss of original color (particularly the bleeding of tar).

Prevention:

Avoid using primers containing tar/asphalt in decorative areas.

Repair:

Sand and re-coat with a more appropriate coating system.

- 8. Blistering

-

Blistering: Dome-shaped protrusions or blisters on the dry coating surface, which may contain liquid, gas, or crystals, due to loss of adhesion between the surface coating and the underlying layer.

Possible Causes:

1. Contamination by grease, salt, rust, trapped moisture, residual solvents, or hydrogen;

2. Pressure (cathodic protection), soluble pigments, etc., causing localized areas;

3. Loss of adhesion;

4. Penetration of moisture causing blistering under immersion conditions;

5. Overcurrent protection can also cause blistering.Prevention:

1. Ensure correct surface treatment and coating application;

2. Use the appropriate coating system;

3. Employ proper cathodic protection.Repair:

Remove the blistered area or the entire coating system depending on the size and type of blistering, and repair or re-coat.

- 9. Bubbles or Bubbling

-

Bubbles: Small, round, hollow bodies protruding from the surface of the coating. Bubbles may be intact or ruptured. They are especially found on thick coatings, particularly with spray or roller application, but should not be confused with blistering.

Possible Causes:

1. Air/solvents trapped within the coating before it dries, causing bubbles;

2. High viscosity of the coating during roller application;

3. Use of incompatible solvents;

4. Incorrect mixing or unskilled application;

5. Exceeding the pot life of a two-component coating.Prevention:

1. Choose the appropriate application method and correct coating thickness based on the type of coating;

2. Thin the coating to the proper viscosity for brushing;

3. Apply within the specified pot life.Repair:

Thoroughly sand the surface based on the distribution and severity of bubbles, then re-coat with a coating of suitable viscosity.

- 10. Bloom/Blush/Amine Sweating

-

Amine Sweating: A mist-like deposit on the coating surface, similar to the fruit bloom on grapes, which causes the coating to lose its gloss and darken.

Possible Causes:

Exposure of the coating to moisture condensation, humidity, or low temperature during curing or drying; or poor ventilation;

Improper solvent mixing can also cause the coating to bloom.Bloom/Blush:

Ammonia and sulfur dioxide form ammonium sulfate on the coating surface;

Amine Sweating and Carbonization:

Amine, carbon dioxide, and moisture react to form ammonium carbonate.Prevention:

Apply and cure coatings under the proper environmental conditions or according to the manufacturer's recommendations.

Repair:

Remove the frost with warm water or a suitable solvent; Apply the intermediate/finish coat according to the manufacturer's recommendations.

- 11. Brush Marks

-

Brush Marks: When brushing, the coating does not level out, and after drying, visible uneven stripes and wrinkles remain on the surface.

Possible Causes:

1. The viscosity of the coating may be too high during brushing;

2. Incorrect solvent used;

3. Insufficient mixing and unskilled application;

4. The two-component coating may have exceeded its use time after mixing.Prevention:

Choose the correct brushing method and appropriate coating thickness based on the type of coating; Dilute the coating to the appropriate viscosity for brushing;

Apply within the recommended use time.Repair:

Thoroughly sand the surface according to the degree of brush marks and reapply with the coating of appropriate viscosity.

- 12. Checking – No Undercoating Exposed

-

Checking: Small cracks that do not penetrate the topcoat of the coating system. Some cracks are so fine that they are not visible without a magnifying glass.

Possible Causes:

1. Checking is usually a stress-related coating defect, resulting from surface movement, aging, absorption and release of moisture, and a lack of plasticity in the coating;

2. The thicker the coating, the more likely checking will occur.Prevention:

Use the correct coating system, correct application method, and appropriate dry film thickness;

Use coatings with better plasticity.Repair:

Sand and remove all the cracked coatings, then correctly reapply the coating system or use coatings with better plasticity and less tendency for cracking.

- 13. Cheesiness

-

Cheesiness: The coating remains soft even after extending the drying time.

Possible Causes:

1. Incorrect mixing ratio of the two-component coating;

2. Too low drying/curing temperature;

3. Excess solvent residue in the coating.Prevention:

Ensure the correct mixing ratio;

Only use the recommended amount of solvent;

Apply and cure the coating in a controlled environment.Repair:

Remove all the soft coating and apply the correct coating system according to the manufacturer's recommendations.

- 14. Wrinkling – Rivelling – Crow’s Footing

-

Wrinkling: A wrinkling phenomenon that appears during the drying process of the coating.

Possible Causes:

1. Usually caused by the rapid drying of the coating surface, while the solvent inside the coating evaporates slowly;

2. Or due to the strong solvent in the topcoat softening the undercoat, and the solvent evaporates slowly;

3. Recoating before the first layer of coating has fully cured.Prevention:

1. Use the correct coating system;

2. Correct application method and proper dry film thickness;

3. Follow the re-coating intervals recommended by the coating supplier.Repair:

Sand and remove the wrinkled coating surface, then reapply.

- 15. Orange Peel

-

Orange Peel: The coating surface is uneven with dimples and protrusions resembling an orange peel.

Possible Causes:

1. Poor flow of the coating (over-thick coating or low temperature).

2. Uneven spraying of the coating.

3. Rapid solvent evaporation.

4. The spray gun is too close to the surface being coated.

5. Improper spraying techniques or use of an unsuitable solvent.Prevention:

Use proper application techniques and choose the right coating system with appropriate formulations.

Repair:

For areas requiring high decorative precision, sand and clean the surface, then re-coat.

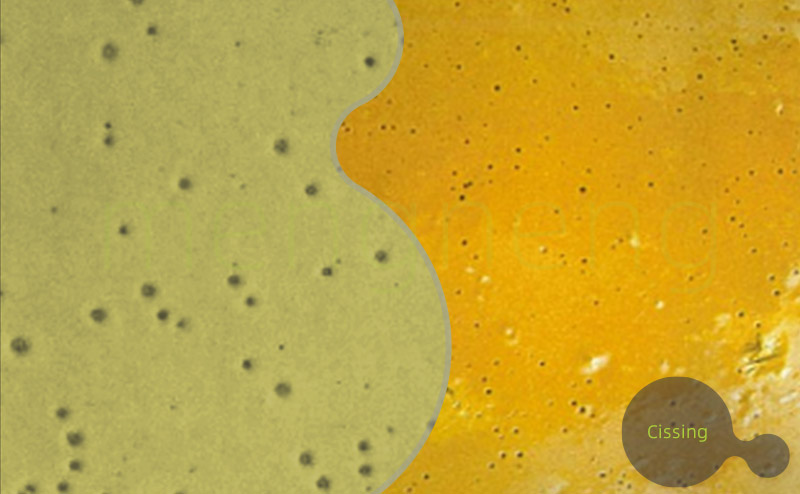

- 16. Cissing/Fisheyes

-

Description: Small tears in the wet coating layer; when the coating shrinks, it reveals the underlying base material. The coating is unable to cover the base material, and these defects can be large.

Possible Causes:

1. The surface is contaminated with moisture or other pollutants like oil, grease, or silicone resin.

2. The use of an unsuitable solvent may also cause this.Prevention:

Ensure the surface is clean and free from oils or other contaminants.

Repair:

Sand and clean the surface properly, then re-coat according to the manufacturer's recommendations.

- 17. Cratering

-

Description: Small depressions on the coating surface that resemble small bowls. This should not be confused with cissing.

Possible Causes:

1. Trapped air or solvent bubbles that burst during the drying of the coating, leaving small craters.

2. Lack of sufficient time for the coating to flow and form an even coat.Prevention:

Improve spraying techniques and ensure there is no air ingress during mixing.

Use solvents as per the supplier's recommendations.Repair:

Sand the surface, clean it, and then re-coat.

- 18. Cold Flow

-

Cold Flow: A plastic deformation caused by the effects of water pressure and friction on the coating layer that has not fully dried yet. In mild cases, it can cause surface unevenness, while in severe cases, it can lead to peeling.

Possible Causes:

1. The coating is not fully dried or cured, and water has entered or operation was started too early.

Prevention:

Ensure the coating is fully dried and cured before exposing it to water or starting operation.

Repair:

Re-coat the affected area.

- 19. Dust Particles

-

Dust Particles: Protrusions on the coating surface where foreign bodies attach to the coating before it dries.

Possible Causes:

1. Environmental factors:

① The spraying environment is not clean with dust and fibers present.

② Insufficient airflow or excessive coating mist.

③ High temperature or rapid solvent evaporation.

2. Mechanical factors:

④ Insufficient spraying pressure or poor spray mist.

⑤ The spray gun is not clean.

3. Human factors:

⑥ Workers' clothes are not clean.

⑦ The vehicle is not clean.

⑧ The base surface was not cleaned of protrusions.

4. Material factors:

⑨ Coating degradation due to deposition or clumping.

⑩ Poor distribution of materials or glitter in the coating.

⑪ The coating was not filtered or filtering was ineffective.Prevention:

1. Regularly clean the coating room, remove dust, and ensure a clean environment.

2. Regularly clean the ventilation system and ensure clean air.

3. Install filters in the coating pipes to ensure good filtration.

4. Use appropriate work clothing to prevent harmful fibers.

5. Train workers on correct spraying practices.Repair:

1. Sand large particles and make local corrections.

2. Grind small particles and then polish the surface.

-

-

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience