Bridge Steel Structure Anti-Corrosion Solve

Corrosion is an unavoidable natural phenomenon in the use of steel structure bridges. With the widespread application of steel structures in bridge construction, corrosion protection has become an important aspect of bridge maintenance and preservation. Currently, both domestically and internationally, most corrosion protection solutions for steel structure buildings use coating methods. Due to the low cost and strong sustainability of coating protection, this paper attempts to propose an innovative solution for the corrosion protection system of bridge steel structures, given the widespread application of coating corrosion protection.

-

Corrosion Background

Corrosion Background -

Design Basis

Design Basis -

Concrete Bridge

Concrete Bridge -

Steel Structure Bridge

Steel Structure Bridge -

Cable Fireproofing

Cable Fireproofing -

Cable Anti-Icing

Cable Anti-Icing -

Special Substrates

Special Substrates -

Maintenance Coating

Maintenance Coating

-

- Corrosion Protection of Steel Structure Bridges

-

I. Background of Bridge Steel Structure Corrosion Protection

Bridges are one of humanity's greatest architectural feats. In a certain sense, bridges are not just auxiliary structures for human life and communication, but also crystallizations of human wisdom and strength, representing masterpieces created by mankind.

The evolution of bridges is closely tied to the development of the coating industry. The development of the coating industry is closely related to the application of raw materials such as resins, additives, and functional pigments. The successful use of each new material leads to the creation of new coating products, which in turn represent the development of bridge coatings at various stages.

II. Hazards of Bridge Corrosion

While the construction of bridges brings enormous convenience to human life and transportation, bridges themselves are also subject to damage and require maintenance or even complete reconstruction. Therefore, researching the causes of bridge damage is necessary for bridge maintenance, and it helps to extend the lifespan of bridges. Looking at the causes of bridge failure, the main factors include poor materials, production defects, natural disasters, traffic accidents, and corrosion. Among these, experts agree that corrosion is one of the primary reasons for bridge damage and failure.

The materials used in bridge construction, especially metal components, are exposed to outdoor environmental conditions, making them prone to chemical and electrochemical reactions with surrounding media (such as moisture, salt, etc.). Bridges are often built over rivers, and their environments typically have high humidity, creating a highly corrosive environment. Bridges are usually made from steel and concrete.

III. Types of Bridge Corrosion

The construction of bridges is typically dictated by the need to span rivers or seas, creating highly complex corrosion environments. China's vast territory and varied geographic locations make the corrosion rate and conditions of each bridge unique. Therefore, it is essential to analyze the corrosion environment before designing the corrosion protection system for bridges.

(1) Climate Characteristics in China

Based on temperature and humidity across different regions, the climate of China is usually categorized into the following five types:

Region Average Annual Rainfall/mm

Average Annual Humidity/%

Frost

Temperature Range/°C

Northwest, South Xinjiang, Tibet, Inner Mongolia, etc.

100~300

<60

-

-30~35

North China, Northeast, Xi'an~Shandong

500~800

60~80

-

-40~35

Sichuan, Chongqing to the Yangtze River Basin, Yunnan, Guizhou

1000~1200

>75

Likely to condense, frost

-20~36

Guangdong, Guangxi, Pearl River Basin

1500~1700

>75

Likely to condense

-5~40

Hainan, Hong Kong

2000

>75

Likely to condense

0~40

Tropical Humid Zone: Leizhou Peninsula, Hainan Island, and the southern part of Taiwan.

Subtropical Humid Zone: South of Qinling, Yangtze River Basin, Sichuan, Pearl River Basin, northern Taiwan, and Fujian.

Subtropical Dry Zone: Gobi Desert south of the Tianshan Mountains in Xinjiang.

Warm Temperate Zone: North of Qinling, southern Inner Mongolia, North China, and southern Northeast.

Cold Dry Zone: Northern Inner Mongolia and Heilongjiang Province.

(2) Atmospheric Corrosion Environment Classification

Bridge corrosion is not only affected by temperature and humidity, but also by corrosive substances in the atmosphere, such as chloride ions, sulfur compounds, and nitrogen oxides. These corrosive substances are produced either directly or indirectly from urban pollutants (such as vehicle exhausts or boiler emissions), industrial emissions, and marine climates.

(3) Corrosion in Water Media

Bridges are often built across rivers and seas, which makes their piers, beams, and other components susceptible to water corrosion. Based on the composition of the water, corrosion in water media is typically categorized as freshwater corrosion and seawater corrosion.

Freshwater Corrosion: Freshwater contains low levels of salt and is generally acidic. The corrosion of freshwater is usually weak and is primarily caused by oxygen absorption. However, with modern industrial pollution in freshwater, corrosion rates are accelerating. External factors like these cannot be ignored.

Seawater Corrosion: Seawater is an electrolyte solution containing various salts. Seawater corrosion is classified into splash zones, tidal zones, fully submerged zones, and sea mud zones. Among these, the splash zone, affected by wind and waves, experiences frequent impacts and wet-dry cycles, which requires the highest corrosion protection.

(4) Soil Corrosion

The supporting columns of bridges are inevitably embedded in soil, and the corrosion of steel or concrete in soil directly impacts the safety of the bridge. The factors contributing to soil corrosion include resistivity, oxygen content, salinity, moisture content, pH value, temperature, and microorganisms.

-

- Bridge Corrosion Protection Design: Basic Principles / Service Life / Protective Coat

-

I. Basic Principles

The corrosion factors affecting bridges vary depending on the environment in which the bridge is located. Therefore, the corrosion protection coating system for bridges must follow a "customized" design concept. Considering the various factors in bridge coating, the basic principles of coating design are generally summarized into the following four key points.

1. Fully consider the corrosion environment of the bridge

As mentioned in the previous section, based on the atmospheric and chemical corrosion environment differences, the corrosion environment of the bridge can be classified by referring to the ISO 12944-2:2017 "Protective coatings for steel structures against corrosion - Part 2: Classification of environments" and GB/T 15957-1995 "Atmospheric corrosion classification" standards.

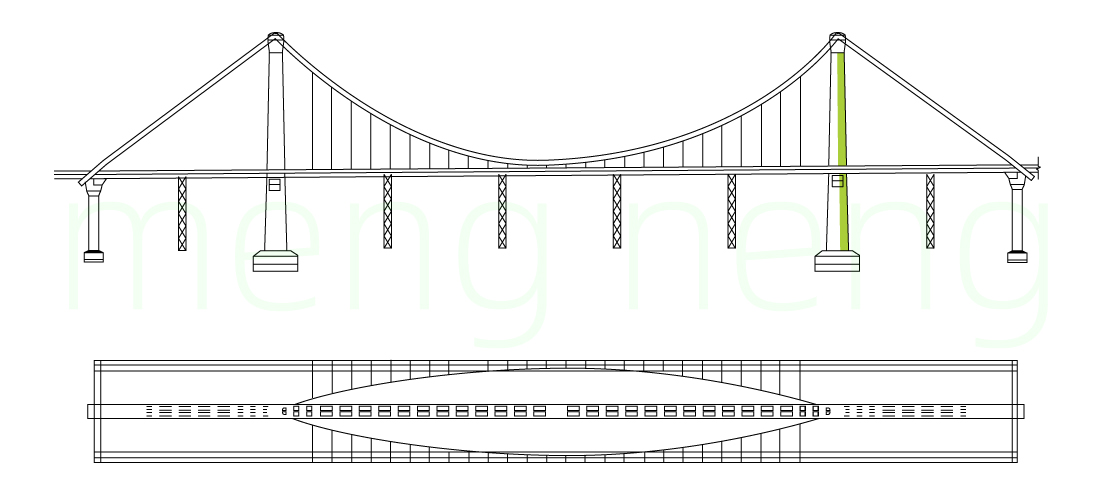

2. Fully consider the structure and working conditions of the bridge, as well as the different structural types and conditions

The requirements for surface treatment and coating work vary greatly and are important bases for customized coating design. These factors mainly include:

● Steel structure or concrete structure;

● Bridge structure types — steel box girder, steel plate girder, steel truss girder, steel pipe arch;

● The specific characteristics of cables and wind vanes in suspension bridges, cable-stayed bridges, and arch bridges;

● The working conditions and microenvironment characteristics of each part of the bridge structure;

● Appearance and color design requirements of the bridge;

● Coordination between the bridge manufacturing process and coating operations.

3. Fully consider the level of construction technology

The protective functions of coatings include cathodic protection, corrosion inhibition, and shielding. Construction technology directly affects surface treatment of the substrate, the film-forming quality of the coating, and thus the performance of the protective functions of the coating. For example, if zinc-rich paint is applied to a steel surface that has not reached Sa2.5 grade surface treatment, the cathodic protection effect will not be satisfactory. Therefore, modern bridge coating emphasizes surface treatment of the substrate, selection of high-quality heavy-duty corrosion-resistant coatings, proper coating system design, strict control of on-site construction quality, and strengthened maintenance during the operational process to ensure and extend the bridge's service life.

4. Fully consider investment limitations

Like any other design, coating design must implement the "Life Cycle Cost Analysis" (LCCA) approach (detailed in Section II of this chapter); controlling investment within the allowable range is essential for feasibility.

II. Service Life of Corrosion Protection Coatings

The service life of a corrosion protection coating system should be selected based on the expected life of the bridge. Generally, for large new bridges, if the coating construction quality is up to standard and proper maintenance and upkeep of the coating are carried out after the bridge is completed and in service, the service life of the protective coating system is generally considered to be 25 years for large steel structure bridges. Some large new bridges in China require the protective coating design service life to be 25-30 years. In particular, the newly released ISO 12944-1:2017 standard clearly stipulates that the maximum durability of steel structure protective coatings is over 25 years, which has driven the design of new bridge corrosion protection coating systems to higher standards.

III. Content of Corrosion Protection Coating Design

The corrosion protection coating design document should mainly include the following content:

1. Coating Design Life

Determine the coating service life of the designed object;

2. Corrosion Environment Analysis

Analyze the corrosion environment of the designed object (C1~C5, CX, Im1, etc.) according to the requirements of ISO 12944-2:2017 and GB/T 15957-1995 standards;

3. Referenced Standards

Include relevant standards such as ISO 12944-2017, Q/CR 749-2020, JT/T 722-2021, and HG/T 3668-2009;

4. Coating System

Based on the coating location, refer to relevant standards to design the coating system;

5. Product Technical Specifications

Based on the designed coating system, refer to relevant standards to determine the technical performance indicators of the coating;

6. Coating Process Plan

This typically includes structural treatment, surface treatment, surface cleaning, environmental checks, and coating operations. Structural treatment includes treating defective parts inside the bridge structure, such as sharp edges and corners; surface treatment includes methods such as shot blasting, sandblasting, mechanical or manual grinding, and acid pickling; surface cleaning includes dust removal, oil and grease removal, and removal of surface salts; environmental checks involve checking the coating construction environment, including steel plate temperature, environmental temperature, relative humidity, dew point, ventilation, lighting, safety, and other factors; coating operations involve selecting the coating method and various conditions according to the coating process plan.

7. Quality Inspection and Acceptance

Conduct quality inspections before and after coating according to the coating design document's requirements, including checking the surface roughness and cleanliness before coating, and checking the coating thickness and pull-off strength after coating. Complete the quality inspection and acceptance process.

IV. Bridge Coating Color Design

Today, bridges are no longer just a traditional tool for facilitating traffic. Many times, bridges represent the image of a city and reflect its characteristics. For example, the steel box girder of the Runyang Yangtze River Bridge is painted in metallic aluminum color, crossing the mighty Yangtze River like a silver galaxy; the cables of the Shantou Kaishi Bridge are cleverly painted in orange-yellow, resembling rays of sunshine spreading across green waves; the Xiaowan Bridge in Yunnan uses ice grey, harmoniously blending with the surrounding green mountains and water, enhancing the tourism appeal. Therefore, bridges have become beautiful scenery lines for cities or regions. As a result, owners are increasingly focusing not only on the corrosion protection performance but also on the appearance of the bridge, especially the choice of the protective coating color.

However, color design is not an easy task. Firstly, human perception of color is very complex. Some colors make people feel calm and comfortable; conversely, some colors make people feel anxious and tense. For drivers crossing the bridge, color also relates to safety. Secondly, color has a significant impact on the cost and durability of the product. Some colors, such as bright red or bright yellow, may use low-cost azo dyes, but have poor weather resistance, which cannot achieve long-lasting protection; using other pigments may increase costs considerably. Therefore, color design has become an essential part of bridge protective coating design. Designers must not only consider the owner's requirements but also take into account safety, cost, and weather resistance.

In summary, the color design should adhere to the principles of harmony between process aesthetics, coating performance, technical economy, and the surrounding environment.

- Design Basis: ISO 12944, Railway, Chemical, and Transportation Industries.

-

I. Fundamental Standards

The coating design of bridges must fully consider the impact of atmospheric corrosion environments. ISO 12944-2:2017 "Protective coatings for steel structures - Part 2: Classification of environments" and GB/T 15957-1995 "Classification of atmospheric corrosion environments" are the most widely used and practical standards in current coating design. Specific classification methods can refer to the section on "Classification of atmospheric corrosion environments" in the first part of this chapter.

II. Industry Standards for Bridge Corrosion Protection Coatings

(1) Railway Industry Standards

In the early days, China’s railway industry formulated four industry standards for steel bridge corrosion protection. Among them, the standard TB/T 2486-1994 "Evaluation of railway steel beam coating degradation" specifies the types, levels, and evaluation methods of coating degradation, applicable to evaluating the condition and quality of steel beam coatings, as well as the classification of degraded coatings for steel beams, and other steel structures; the standard TB/T 1527-2004 "Protective coatings for railway steel beams" specifies the technical requirements, test methods, and inspection rules for protective coatings on railway steel bridges, applicable to the initial coating, recoating after coating degradation, and maintenance coatings for steel bridges; the standard TB/T 2772-1997 "Technical conditions for the supply of anti-rust primers for railway steel bridges" and TB/T 2773-1997 "Technical conditions for the supply of topcoats and intermediate coats for railway steel bridges" respectively specify the classification, technical requirements, test methods, inspection rules, packaging, marking, transportation, and storage of anti-rust primers, intermediate coats, and topcoats for railway steel bridges. These standards are applicable to new construction, re-coating of steel beams in operation, and maintenance coating, as well as anti-rust primers, intermediate coats, and topcoats used for other steel structures. In 2011, TB/T 2772-1997 and TB/T 2773-1997 were abolished and merged into TB/T 1527-2011 "Technical conditions for protective coatings and coatings supply for railway steel bridges."

In 2020, the original Ministry of Railways standard TB/T 1527-2011 was abolished and replaced by the newly formulated China Railway Corporation enterprise standard Q/CR 749-2020 "Protective coatings and coatings for railway bridge steel structures and components." This standard is divided into three parts: Part 1: Steel bridges; Part 2: Bearings; Part 3: Pedestrian steel beams and auxiliary steel structures. It specifies the protective coating systems, technical requirements, inspection methods, inspection rules, as well as coating packaging, marking, transportation, and storage for these three types of structures, and applies to initial coatings, re-coating after coating degradation, and maintenance coatings for these structures, as well as the anti-rust primers, intermediate coats, and topcoats used for coating.

(2) Chemical Industry Standards

The standard HG/T 3656-1999 "Steel structure bridge coatings" classifies steel bridge coatings into two categories based on service life: ordinary type and long-lasting type. It specifies the technical requirements, test methods, inspection rules, and packaging, marking, transportation, and storage for anti-rust primers, intermediate coats, and topcoats for these two types of products. At the same time, the appendix lists common varieties of both product types and introduces several practical application coating systems.

(3) Transportation Industry Standards

JT/T 722-2008 "Technical conditions for the coating of highway bridge steel structures"

JT/T 694-2007 "Technical conditions for corrosion protection coatings for main cables of suspension bridges"

JT/T 695-2007 "Technical conditions for surface coatings for concrete bridges"

Among them, JT/T 722-2008 was revised in 2020. The newly revised standard reflects the advanced and forward-looking nature of coatings and coating technologies in the transportation bridge field. While promoting advanced, mature technologies and successful experiences, it also provides methods and basis for the introduction of new products, new technologies, and new processes. The revision emphasizes the durability, life-cycle economy, and environmental protection of bridges, taking into account recent developments in bridge corrosion protection coatings in China, including both successes and lessons learned, while also referencing advanced international experience, especially the latest version of ISO 12944 and foreign bridge corrosion protection coating standards; JT/T 694-2007 applies to the corrosion protection coatings for the main cable system of suspension bridges. In addition to defining related terminology and definitions, it focuses on design provisions for the coating system of the main cable system, construction process, material performance indicators, and acceptance, safety, health, and environmental protection requirements; JT/T 695-2007 standard designs surface coating systems and performance indicators for concrete bridges under various corrosion environmental conditions, and sets out specific requirements for coating construction, acceptance, safety, health, and environmental protection. Both JT/T 694-2007 and JT/T 695-2007 standards will be revised in the coming years.

-

- Concrete Bridge Renovation and Anti-corrosion Solution

-

I. Concrete Bridge Renovation

Since concrete is an alkaline building material, it is essential for concrete protective coatings to have good alkali resistance, adhesion, and impermeability. Additionally, the coating itself should possess excellent weather resistance and long-term durability. For concrete structures on coastal bridges, the surface coating should have outstanding weather resistance, UV and sunlight degradation resistance, salt spray resistance, and marine atmospheric corrosion resistance, without severe chalking, discoloration, peeling, cracking, or other issues during the effective protection period.

According to the technical specifications for corrosion protection of concrete structures in port engineering (JTJ275-2001), industrial building corrosion protection design specifications (GB50046-95), and building corrosion protection construction and acceptance specifications (GB50212-2002), epoxy resin coatings, polyurethane coatings, chlorinated rubber coatings, vinyl resin coatings, and acrylic resin coatings are considered suitable coating types. Based on domestic and international experience with concrete corrosion protection coatings for bridges, the following coatings are recommended to achieve good coating results.

A1: DreamCover Coating System for Atmospheric Zone of Bridge Surface, Pier Caps, Piers, Guardrails, Pavement Renovation

Design Basis ISO12944-5:2017 Protective Coating Systems for Corrosion Protection of Steel Structures Environmental Conditions C4 High; External: Medium salinity industrial and coastal areas Design Life VH Ultra Long Life Surface Treatment ISO 8501-1 St2: Thorough hand and power tool rust removal from steel surfaces should be free of visible grease and dirt, and there should be no loosely attached oxide scales, rust, or paint layers. Coating Areas Atmospheric zone of bridges, pier caps, bridge deck, piers, guardrails, pavement Coating Coating Type Coating Name Color Thinner A:B Ratio Film Thickness (μm) First Coat DreamCover Graphene Low Surface Treatment Primer DreamCover 220 Gns Grey, Light Grey, Red-Brown, White, Semi-Gloss Graphene Special Thinner DreamThinner 17 Gns 25:5 220 Second Coat DreamDur Fluorocarbon Finish Coat DreamDur 22F RAL and National Standard Colors Special Thinner DreamThinner X 22.73:2.27 80 Total 300 A2: DreamCover Coating System for Bridge Pier Underwater and Wet-Dry Alternating Zones Renovation

Design Basis ISO12944-5:2017 Protective Coating Systems for Corrosion Protection of Steel Structures Environmental Conditions Im1; Freshwater: Facilities installed on rivers, hydropower stations Design Life VH Ultra Long Life Surface Treatment ISO 8501-1 St2: Thorough hand and power tool rust removal from steel surfaces should be free of visible grease and dirt, and there should be no loosely attached oxide scales, rust, or paint layers. Coating Areas Bridge pier underwater section, wet-dry alternating zones Coating Coating Type Coating Name Color Thinner A:B Ratio Film Thickness (μm) First Coat DreamCover Graphene Glass Flake Primer DreamCover 152 Gns Black, Yellow Graphene Special Thinner DreamThinner 17 Gns 23.3:3.7 300 Total 300

- New Construction Plan for Concrete Bridge

-

I. Corrosion Threats Facing Concrete Bridges

Since concrete is a highly alkaline building material, DreamCoatings experts believe that the concrete anti-corrosion coating must have good alkali resistance, adhesion, and impermeability. In addition, the coating itself should have good weather resistance and long-term durability. For coastal concrete bridge structures, the surface coating should have excellent weather resistance, UV and sunlight degradation resistance, salt mist and marine atmospheric corrosion resistance, and should not exhibit severe chalking, discoloration, peeling, or cracking during the effective protection period.

Reinforced Steel Corrosion

Chloride Ion Erosion: Chloride ions in seawater, saline soil, de-icing salts, etc., can penetrate into the concrete, destroying the passivation film on the surface of the steel bars, leading to steel corrosion.

Carbonation: Carbon dioxide (CO2) in the air reacts with calcium hydroxide (Ca(OH)2) in the concrete to form calcium carbonate (CaCO3), reducing the pH value of the concrete and diminishing the protective effect on the steel.

Moisture and Oxygen: Steel bars exposed to moisture and oxygen environments are prone to electrochemical corrosion.

Concrete Deterioration

Carbonation: Concrete carbonation not only lowers the pH value of the concrete, reducing the protection of the steel, but also leads to a decline in the structural performance of the concrete.

Freeze-Thaw Cycle: In cold regions, the water inside the concrete freezes and expands. Repeated freeze-thaw cycles cause micro-cracks to form inside the concrete, ultimately leading to spalling.

Sulfate Attack: When concrete comes into contact with sulfate-containing groundwater or soil, sulfate ions react with calcium ions in the concrete, producing expansive products that cause the concrete to swell and eventually crack.

Physical Damage

Physical Impact: External physical factors such as vehicle collisions and falling rocks can cause concrete damage.

Vibration: Long-term traffic loads and vibrations can also lead to concrete fatigue damage.

Chemical Erosion

Acidic Environments: In some industrial areas or under acid rain conditions, concrete may suffer erosion from acidic substances.

Other Chemicals: Certain solvents, oils, and other chemicals may also cause damage to concrete.

Microbial Corrosion

Microbial-induced corrosion: In specific environments, microbial activity may promote the corrosion process of concrete and steel reinforcement.

These corrosion threats affect the safety and durability of concrete bridges, so appropriate protective measures should be taken to extend the lifespan of the bridge, such as using high-quality concrete, implementing cathodic protection, and performing regular inspections and maintenance.

II. Anti-Corrosion Solution for Concrete Bridges Using Graphene Coatings

Reference Standard: JT/T 695-2007 Concrete Bridge Structure Surface Coating Anti-Corrosion Technical Conditions

Concrete bridges are classified mainly based on their structure and components. Typically, a concrete bridge consists of the following basic components:

Bridge Deck: The bridge deck is the platform on the top of the bridge used to support vehicles and pedestrians. The deck is typically made of asphalt, concrete, or steel plates to ensure strength and durability.

Bearings: Bearings are the connection points between the bridge and its foundation, designed to support the weight of the bridge and the loads applied to it, transferring these forces to the foundation. Bearings are typically made of rubber or steel to provide good load-bearing capacity and damping effects.

Main Beams: The main beams are the primary structural elements of the bridge, responsible for bearing the load on the bridge and transferring it to the bearings. They are typically made of concrete, steel, or prestressed concrete, offering high strength and durability.

Piers: The piers are the vertical support structures of the bridge, used to support the main beams and the loads on the bridge. Piers are typically made of concrete or steel, providing good load-bearing capacity and structural stability.

Foundation: The foundation is the structure that supports the bridge on the ground. Foundations are typically made of concrete or steel, providing sufficient strength and stability to bear the loads on the bridge.

Additionally, the bridge may include other components such as connecting beams, bearing platforms, columns, cap beams, bearing pads, etc. These parts work together to ensure the structural safety and stability of the bridge.

B1. DreamCoatings Recommended Anti-Corrosion Solutions for Atmospheric Area Bridges, Pier Caps, Decks, Piers, Barriers, and Pavement

Design Basis ISO12944-5:2017 Protective Paint Systems for Steel Structures Against Corrosion Environmental Conditions C4 High; External: Medium salt content industrial and coastal areas Design Life VH Ultra Long Term Surface Treatment ISO 8501-1 St2: Thorough manual and power tool rust removal from steel surfaces should ensure no visible grease, dirt, or loose oxide scale, rust, or paint layers. Coating Areas Atmospheric area bridges, pier caps, decks, piers, barriers, and pavement Coating Coating Type Coating Name Color Thinner A:B Mixing Ratio Film Thickness (μm) First Coat DreamCover Concrete Sealer DreamCover Clear 600 Transparent Epoxy Thinner DreamThinner 17 15:3 40 Second Coat DreamCover Graphene Low Surface Treatment Primer DreamCover 220 Gns Gray, Light Gray, Red-Brown, White Semi-Gloss Graphene-Specific Thinner DreamThinner 17 Gns 25:5 180 Third Coat DreamDur Fluorocarbon Topcoat DreamDur 22F Supports RAL, National Standard Color Matching Special Thinner DreamThinner X 22.73:2.27 80 Total 300 B2. DreamCoatings Recommended Anti-Corrosion Solutions for Bridge Pier Underwater, Wet-Dry Alternate Areas

Design Basis ISO12944-5:2017 Protective Coatings for Steel Structures against Corrosion Environmental Conditions Im1; Freshwater: Facilities installed on rivers, hydropower stations Design Life VH Very Long Life Surface Treatment ISO 8501-1 St2: Thorough rust removal with hand and power tools from steel surfaces should be free of visible grease and dirt, and there should be no loosely attached oxide scales, rust, or paint layers. Coating Parts Submerged parts of the bridge pier, wet-dry alternating zones Coating Coating Type Coating Name Color Thinner A:B Ratio Film Thickness First Coating DreamCover DreamCover Clear 600 Concrete Sealer Transparent Epoxy Thinner DreamThinner 17 15:3 40 Second Coating DreamCover Graphene Glass Flake Primer DreamCover 152 Gns Black, Yellow Graphene Thinner DreamThinner 17 Gns 23.3:3.7 300 Total 340

-

- New Construction Solution for Steel Structure Bridges

-

I. Corrosion of Steel Structure Bridges

Steel structure bridges are exposed to outdoor sunlight and rain, and are easily corroded by various media. If there is no effective corrosion protection method, the service life of the steel bridge will significantly decrease, possibly leading to premature failure.

1. Uniform Corrosion

Uniform corrosion is the most common form of corrosion. Its main characteristic is that the corrosion is distributed evenly across the entire metal surface, gradually thinning the metal at a consistent rate. Although uniform corrosion causes significant metal loss, it is not particularly dangerous, as the corrosion rate is predictable and preventable. With proper engineering design and corrosion protection measures, sudden corrosion incidents in steel bridges are rare.

2. Pitting Corrosion

In suitable environmental media, most of the steel surface remains unaffected by corrosion, but localized pits or spots can form due to selective corrosion of the metal. Over time, these pits grow deeper. Pitting corrosion is generally caused by Cl - ions adsorbing at defect sites in the metal surface film. For example, in December 1988, a stay cable in a cable-stayed bridge in Guangdong broke in January 1995 due to corrosion from Cl - pitting, as revealed by analysis of the corrosion products.

3. Crevice Corrosion

Crevice corrosion occurs in areas where metal surfaces are connected, such as metal-to-metal, or metal-to-non-metal junctions, where a crevice is present. It happens when corrosive media exist in these gaps, particularly in riveted, bolted, and screwed connections, or between flange gaskets and metal parts.

II. Coating Protection for Bridge Steel Structures

Common methods of corrosion protection for steel structures can be divided into two categories: one involves mechanical isolation, where inert materials are used to cover the steel structure surface, isolating it from corrosive media such as water and oxygen; the other involves electrochemical corrosion principles, where the steel structure's potential is artificially elevated, making it the more positive pole, thereby providing protection. Based on these principles, common methods of corrosion protection for steel structures include flame spraying, hot-dip galvanizing, coating applications, and arc spray composite coatings.

Coating protection for steel bridges has been in use for over 100 years. Through continuous development and widespread application, specialized coatings for bridge structures have been developed. Since no single coating can simultaneously provide isolation, UV resistance, and cathodic protection, a comprehensive corrosion protection system for steel bridges typically consists of a primer, intermediate coat, and topcoat, which combine mechanical shielding, passivation corrosion inhibition, and cathodic protection.

A1. Inner Surface of Wind Fairing and Structural Braces

The wind fairing is a special structure in the cross-section of a steel box girder, consisting of the upper and lower plates and webs to improve the aerodynamic properties and increase the bridge's wind stability. The wind fairing is designed to reduce the resonance effects of strong winds on the bridge deck.

Design Basis ISO 12944-5: 2017 Paint and Varnish Protective Coating Systems for Corrosion Protection of Steel Structures Environment C5 Very High; External: High humidity and harsh weather in industrial and high-salinity coastal areas Design Life VH Ultra-long Surface Treatment ISO 8501-1 Sa2.5: Thorough abrasive blasting or shot-blasting. Steel surfaces should be free from visible grease, dirt, oxide scale, rust, or paint coatings. Any remaining traces should be minimal and only dot-like or streaky discoloration. Coating Location Inner surface of wind fairing and structural braces Coating Coating Type Coating Name Color Thinner A:B Ratio Film Thickness (μm) First Layer DreamZinc Graphene Zinc Primer DreamZinc 30 Gns Graphite Gray Graphene Thinner DreamThinner 17 Gns 30.8:3.2 80 Second Layer DreamCover Epoxy Micaceous Intermediate Coating DreamCover 150 Light Gray Mica Iron Oxide Epoxy Thinner DreamThinner 17 25.2:6.8 140 Third Layer DreamDur Acrylic Polyurethane Topcoat DreamDur 550 Custom or National Standard Colors Polyurethane Thinner DreamThinner 10 21.4:3.6 80 Total 300 * The above solution uses the fourth-generation graphene coating. For other solutions, please contact us.

A2, External Surface of Auxiliary Facilities

Bridge auxiliary facilities include the bridge deck system, expansion joints, bridge head slabs, cone slopes, drainage facilities, etc.

Design Basis ISO12944-5:2017 Protective Coating Systems for Steel Structures against Corrosion Environmental Conditions C5 very high; External: High humidity and severe weather industrial areas and coastal areas with high salinity Design Service Life VH ultra-long service life Surface Treatment ISO 8501-1 Sa2.5: Very thorough blasting or shot blasting. The steel surface must be free of visible grease, dirt, scale, rust, paint coatings, or other contaminants. Any remaining marks should only be light spot or strip marks. Coated Areas Bridge deck system, expansion joints, bridge head slabs, cone slopes, drainage facilities, etc. Coating Coating Type Coating Name Color Compatible Thinner A:B Ratio Film Thickness (μm) First Coat DreamCover Graphene Low Surface Treatment Primer DreamCover 220 Gns Grey, Light Grey, Red-Brown, White Semi-gloss Graphene Thinner DreamThinner 17 Gns 25:5 220 Second Coat DreamDur Fluorocarbon Topcoat DreamDur 22F Supports L'Oréal and National Color Standards Special Thinner DreamThinner X 22.73:2.27 80 Total 300 * The above solution uses the fourth-generation graphene coating solution. For other solutions, please contact us.

A3. Steel Box Girder, Steel Anchor Box, Node Connector

Steel Box Girder: A steel box girder is a type of bridge structure with a cross-section resembling a box, made from welded steel plates. It is mainly used in the construction of large-span bridges due to its structural rigidity, strong load-bearing capacity, light weight, and excellent seismic performance.

Steel Anchor Box: A steel anchor box is a structure used to fix the main cables or stay cables of suspension or cable-stayed bridges. It mainly bears the tension transmitted from the main cables or stay cables and evenly distributes these forces to the bridge towers or piers.

Node Connector: A node connector is a connecting element used at the nodes of steel structures, designed to connect members in multiple directions, such as the rods in a truss structure. It is a high-strength connection method capable of bearing large axial and shear forces.

Design Basis ISO12944-5:2017 Protective Coating Systems for Steel Structures to Prevent Corrosion Environment C5 very high; External: Industrial areas with high humidity, severe weather conditions, and coastal areas with high salinity. Design Service Life VH ultra-long-term Surface Treatment ISO 8501-1 Sa2.5: Very thorough abrasive blasting or shot blasting. The steel surface should be free of visible grease, dirt, mill scale, rust, paint coatings, or other contaminants. Any remaining traces should be only slight, point-like or streaky discoloration. Coating Areas Steel box girders, steel anchor boxes, node connector connections Coating Paint Type Paint Name Color Compatible Thinner A:B Ratio Film Thickness (μm) First Coat DreamZinc Cold Spray Zinc DreamZinc 96 Zinc grey Cold Spray Zinc Thinner DreamThinner 16 AX 30:0 100 Second Coat DreamCover Cold Spray Zinc Sealer DreamCover 167 Grey, Matt Epoxy Thinner DreamThinner 17 27:4.5 200 Total 300 *The above solution uses the third-generation cold spray zinc coating. For other solutions, please contact us.

A4. Box Girder, Node Connector External Surfaces

Box Girder: A box girder is a beam structure with a closed cross-section, typically used in the design of long-span bridges such as continuous beam bridges or cantilever beam bridges. The box girder consists of a top plate, bottom plate, and side webs, forming a closed box-shaped structure.

Node Connector: A node connector refers to a connector used at steel structure joints to connect components in multiple directions, such as the members in a truss structure. It is a high-strength connection method capable of withstanding significant axial and shear forces.

Design Basis ISO12944-5:2017 Protective Paint Systems for Steel Structures to Prevent Corrosion Environmental Conditions C5 very high; external: industrial areas with high humidity, severe weather, and high salinity coastal areas. Design Lifespan VH ultra-long-term Surface Treatment ISO 8501-1 Sa2.5: Very thorough jet or blast cleaning. The steel surface must be free from visible grease, dirt, mill scale, rust, paint, etc., with any remaining traces being light spotty or streaky discolorations. Coating Location Box Girder, Node Connector External Surfaces Coating Paint Type Paint Name Color Thinner A:B Ratio Film Thickness (μm) First Layer DreamZinc Cold Spray Zinc DreamZinc 96 Zinc gray Cold spray zinc thinner DreamThinner 16 AX 30:0 80 Second Layer DreamCover Cold Spray Zinc Sealer DreamCover 167 Gray, matte Epoxy thinner DreamThinner 17 27:4.5 120 Total 200 *The above solution uses the third-generation cold spray zinc coating solution. For other solutions, please contact us.

A5. Box Girder Interior Surface

The corrosion protection of the box girder interior surface is equally important because the interior of the box girder is prone to moisture accumulation and poor ventilation, making it a particularly vulnerable area for corrosion.

Design Basis ISO12944-5:2017 Protective Paint Systems for Steel Structures to Prevent Corrosion Environmental Conditions C5 very high; external: industrial areas with high humidity, severe weather, and high salinity coastal areas Design Lifespan VH ultra-long-term Surface Treatment ISO 8501-1 Sa2.5: Very thorough jet or blast cleaning. The steel surface must be free from visible grease, dirt, mill scale, rust, paint, etc., with any remaining traces being light spotty or streaky discolorations. Coating Location Box Girder, Node Connector External Surfaces Coating Paint Type Paint Name Color Thinner A:B Ratio Film Thickness (μm) First Layer DreamZinc Cold Spray Zinc DreamZinc 96 Zinc gray Cold spray zinc thinner DreamThinner 16 AX 30:0 80 Second Layer DreamCover Cold Spray Zinc Sealer DreamCover 167 Gray, matte Epoxy thinner DreamThinner 17 27:4.5 120 Total 200 *The above solution uses the third-generation cold spray zinc coating solution. For other solutions, please contact us.

-

- Fire Protection for Suspension Bridges

-

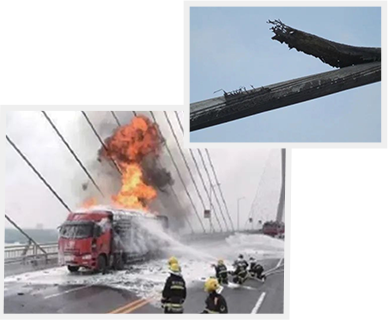

I. Impact of Fire on the Main Cables of Bridges

With the increasing number of vehicles and traffic volume, fire accidents caused by traffic accidents on cable-supported bridges occur from time to time. As an important load-bearing component of cable-supported bridge systems, cables have relatively good mechanical properties and weather resistance, but the fire resistance of materials such as high-strength steel wires, polyester fiber bands, PE sheaths, and anti-corrosion coatings is poor. When a fire occurs on the bridge deck (especially in the case of oil tanker fires), the PE sheath is prone to burning, the temperature of the steel wire increases continuously, the anti-corrosion layer may peel off, and the performance of the steel wire may degrade, causing serious fire damage to the bridge and threatening the safe operation of the bridge, as shown in Table 1 and Figure 1. Currently, there are no fire protection design standards for load-bearing steel structures, so there are no corresponding guidelines on how to protect important steel components such as cables in fire scenarios.

Suspension bridges, due to their unique structural design, have become an important part of modern bridge engineering. However, this structure faces serious safety challenges when exposed to fire. The main cables, as the core component of the suspension bridge, have critical fire protection requirements to ensure the overall safety of the bridge. This article aims to explore and propose a comprehensive fire protection coating solution to enhance the fire resistance of the main cables in case of fire.

1. Fire Challenges for the Main Cables of Suspension Bridges

The main challenges faced by suspension bridges in fires include:

Heat damage to main cables: High temperatures may cause the main cables to lose strength or even break.

Structural stability: The high temperatures generated by the fire may affect the overall structural stability of the bridge.

Rescue difficulty: The height and span of the suspension bridge make firefighting and rescue operations more complicated.

Table 1: Fire Damage Accidents of Cable-Supported Bridges

Serial No. Date of Accident Bridge Name Cause of Fire 1 April 2009 Wuhu Certain Cable-Stayed Bridge Passenger car fire 2 October 2011 Nanjing Certain Cable-Stayed Bridge Truck self-ignition 3 November 2011 Harbin Certain Bridge Multiple vehicle fires 4 October 2014 Guangdong Panyu Bridge Truck self-ignition 5 January 2014 Zhengshao Expressway Certain Bridge Gasoline tanker fire 6 June 2017 Guangkun Expressway Certain Bridge Truck self-ignition 7 March 2018 Hubei Certain Cable-Stayed Bridge Truck self-ignition 8 July 2020 Wuhan Certain Cable-Stayed Bridge Truck self-ignition 9 July 2021 Nanjing Certain Suspension Bridge White oil tanker fire 10 September 2022 Anhui Certain Overpass Silicone oil tanker fire II. Issues with Traditional Fireproof Materials

Bridge cable fireproof materials need to meet the requirements of both fire resistance and thermal insulation. Additionally, in order to satisfy the need for wrapping cables, the materials must have a certain degree of flexibility. Furthermore, as a semi-permanent protective measure for bridges, the cable fireproof system must also consider the requirement for environmental aging resistance, such as UV aging resistance, water resistance, acid rain corrosion resistance, and the ability to adapt to structural vibrations of the bridge.

After extensive research and comparisons, materials with potential for cable fireproof and thermal insulation applications mainly include felt-type fireproof materials such as basalt fiber needle-punched felt, ceramic fiber needle-punched felt, or aerogel thermal insulation felt. Felt products also need to be further classified based on performance parameters such as mechanical strength, temperature resistance, and thermal conductivity. The advantages and disadvantages of the main fireproof materials are shown in Table 2.

Material Category Material Performance Suitability for Cables Cotton-based Asbestos Carcinogenic substance, officially banned Not suitable Ultrafine Glass Wool Poor heat resistance, moderate insulation effect Not suitable Rock Wool Cheap, low-end, low strength, poor insulation Not suitable Board-based Calcium Silicate Board High rigidity, poor flexibility Not suitable Basalt Board High rigidity, poor flexibility Not suitable Aluminum Silicate Board High rigidity, poor flexibility Not suitable Coating-based Fireproof Coating Poor PE adhesion, low strength, prone to cracking Not suitable Felt-based Basalt Fiber Felt Moderate thermal conductivity, high strength, moderate heat resistance Potential application Ceramic Fiber Needle-punched Felt Moderate thermal conductivity, moderate strength, excellent heat resistance Potential application Ordinary Aerogel Thermal Insulation Felt Low thermal conductivity, moderate strength, moderate heat resistance Potential application A1. Main Cable Fireproof Coating

DreamGel Aerogel Fireproof Coating is a new type of coating made from aerogel material, with the following features:

1. Low thermal conductivity: The pore size of aerogel typically ranges from 2 nm to 50 nm, and this nanoscale pore structure significantly reduces thermal conductivity. The very low thermal conductivity means it can effectively isolate heat and reduce the transfer of thermal energy from the high-temperature area to the low-temperature area. It can reach 0.013 W/m·K under normal temperature and pressure.

2. High insulation efficiency: The pore structure of aerogel prevents air molecules from moving between the pores, thereby reducing thermal convection. This structure also reduces heat radiation, further improving insulation performance.

3. High-temperature resistance: Aerogel itself is a high-temperature-resistant material that can maintain structural stability even in high-temperature conditions. Therefore, DreamGel Fireproof Coating can maintain its insulation performance in high-temperature environments for extended periods.

4. Improved material strength and adhesion: Through formula adjustments, the mechanical strength and adhesion to the substrate of the coating can be further improved, ensuring the integrity and long-term performance of the coating.

5. Waterproof and corrosion-resistant: DreamGel Fireproof Coating has excellent waterproof properties, preventing moisture penetration. Water absorption rate >99%. At the same time, it is also resistant to corrosion, protecting the substrate from chemical erosion.

6. Fire-resistant performance: Aerogel itself is a non-flammable material, which improves the overall fire resistance of the coating. When the coating forms a layer, it can effectively isolate flames from contacting the substrate, preventing flame spread. Fire rating: A1, Smoke rating: AQ1.

7. Environmentally friendly: DreamGel Fireproof Coating generally contains no volatile organic compounds (VOCs), making it environmentally and human-friendly.

8. Easy construction: DreamGel Fireproof Coating can be applied using conventional spraying or brushing methods, making it convenient and quick. However, it is important to ensure the coating layer is applied tightly during construction to achieve the best insulation effect.

9. Strong adaptability: It can be applied to various substrates such as metal, concrete, etc., making it suitable for use in buildings, equipment, and many other scenarios.

10. Extended service life: Due to its excellent insulation and fireproof properties, DreamGel Fireproof Coating can effectively protect the substrate and extend the service life of the structure.

In summary, DreamGel Fireproof Coating has gained widespread application in both industrial and civil construction due to its excellent insulation and fireproof performance. Proper application and maintenance during construction are crucial to ensuring its long-term effectiveness.

Design Basis ISO12944-5:2017 Paint and Varnish Protection Systems for Steel Structures against Corrosion Environment C5 Very High; External: Industrial areas with high humidity and severe weather, and high salinity coastal areas Design Life VH Ultra-long Surface Treatment ISO 8501-1 St2: The surface of steel cleaned by manual and power tools should be free from visible grease and dirt, and there should be no loosely attached oxide scale, rust, or paint layers. Coating Areas Main cables, suspender cables, and stay cables Coating Coating Type Coating Name Color Accompanying Thinner A:B Ratio Film Thickness (μm) First Coat DreamTherm Aerogel Fireproof Layer DreamHeat 100 White / 14:0 10000 Total 10000

-

- Cable Ice Prevention Solution

-

I. Hazards of Ice Formation on Bridge Cable Stays

Cable stays on cable-stayed bridges and the lower part of suspensions cables on suspension bridges are exposed to the bridge deck. During winter, with lower temperatures, higher wind speeds, and high humidity, bridge cables are highly susceptible to ice formation. The formation of ice on bridge cables brings a series of safety risks and potential hazards, including the following:

1. Increased load on cables: The weight of ice adds extra load to the cables. Especially when ice accumulates heavily, it may cause an imbalance in cable tension, which could affect the overall stability and safety of the bridge structure.

2. Reduced cable strength: Ice formation can cause changes in the physical properties of the cable materials. For instance, in extreme cold, certain materials may become brittle, reducing the cable's tensile strength.

3. Formation of icicles: Water droplets formed from melted ice at the bottom of the cables during the day freeze again at night, forming icicles. When the icicles grow to a certain size or the cable's temperature rises, the base of the icicle can break off and fall, posing a danger to pedestrians and vehicles on the bridge deck.

4. Increased friction: Ice formation increases friction between cables, affecting their normal movement and the dynamic characteristics of the bridge, especially when the cables need to move or adjust tension.

5. Impact on structural stability: Ice formation on cables reduces the overall structural stability of the bridge, particularly under severe weather conditions such as high winds, which may exacerbate bridge vibration or swaying.

6. Increased maintenance costs: Ice formation damages the surface of the cables, leading to more frequent and costly maintenance. Moreover, the presence of ice makes maintenance work more challenging.

7. Safety hazards: The falling icicles pose a direct threat to pedestrians and vehicles on the bridge deck and may also endanger boats or other objects below the bridge.

8. Aesthetic impact: Ice formation damages the aesthetic appearance of the bridge, especially when icicles form on the cables. While it might look spectacular, it also represents a safety risk.

9. Traffic disruption: Severe ice formation affecting the safety of the bridge could lead to traffic disruptions or restrictions, hindering people's movement. To prevent these hazards, Mengneng Coatings has developed anti-icing and de-icing technologies, including carbon nanotube materials applied to the cables with a superhydrophobic coating or using heating cables and vibration devices to prevent ice formation. Additionally, hydrophobic coatings and chemical anti-icing agents can be used to reduce ice layer formation. These Mengneng coating technologies help improve the reliability and safety of bridge cables in winter.

II. Using Mengneng Carbon Nanotube Coatings to Solve Cable Ice Formation

Applying carbon nanotube materials on bridge cables, combined with a superhydrophobic coating, can prevent ice formation through heating in low-temperature environments. Mengneng’s carbon nanotube coating technology has very high electrical conductivity and some resistance. When current flows through the carbon nanotubes, heat is generated due to the resistance effect. This heating method is highly efficient and controllable, allowing rapid temperature increase of the cables to melt the ice or prevent ice formation.

2.1. Advantages of Carbon Nanotube Coating Technology

Mengneng Technology blends carbon nanotubes with coatings to form a composite material. This composite material can be directly wound around or embedded in the cables, forming a heating system.

1. High efficiency and energy saving: Carbon nanotubes heat up quickly and have high energy conversion efficiency.

2. Even heating: Carbon nanotubes provide uniform heat distribution, avoiding localized overheating.

3. Lightweight: Carbon nanotube heating elements are thin and lightweight, not adding load to the cables.

4. Flexibility: Heating elements can be customized in shape and size based on the specific needs of the cables.

2.2. Mengneng Anti-Icing Coating Solution

Mengneng’s anti-icing paint comes in a two-component package, consisting of a fluorocarbon resin, pigments, solvents, additives, and another component being aliphatic isocyanate hardener, aimed at preventing ice formation or reducing ice layer formation on surfaces. This type of coating typically has the following features:

1. Low surface energy: Mengneng anti-icing paint has low surface energy, making it difficult for water or ice to adhere to the coating.

2. Superhydrophobicity: Mengneng anti-icing paint exhibits superhydrophobic properties, significantly reducing the contact area between water droplets and the surface.

3. Large contact angle: The anti-icing coating's contact angle reduces ice adhesion, allowing ice to slide off the surface more easily.

4. Low friction coefficient: The surface of Mengneng anti-icing paint typically has a low friction coefficient, making it difficult for ice layers to firmly adhere to the surface.

5. Self-cleaning function: Because the anti-icing paint reduces ice formation, it also reduces the cleaning workload.

6. Weather resistance: Anti-icing paints generally have good weather resistance, maintaining their performance in outdoor environments for long periods.

7. Easy application: Mengneng anti-icing paint can be applied using common painting methods such as spraying or brushing.

Mengneng’s anti-icing paint is widely used in: aircraft surfaces to prevent icing and ensure flight safety; electrical wires and cables to prevent ice-related faults; bridges, road signs, and more to reduce safety risks from ice formation; wind turbine blades to prevent icing and improve power generation efficiency.

Design Basis ISO 12944-5: 2017 Protective Paint Systems for Steel Structures Against Corrosion Environment C5 Very High; External: Industrial areas with high humidity and harsh weather, coastal areas with high salinity Design Lifespan VH Very Long Surface Treatment ISO 8501-1 St2: Surface is smooth and flat Coating Locations Cables Coating Coating Type Coating Name Color Thinner A:B Ratio Film Thickness (μm) First Layer Carbon Nanotube Material Carbon Nanotube Heating Film Black / / 0 Second Layer DreamDur Mengneng Anti-Icing Paint DreamDur 660 White / 22.73:2.27 80 Total 80

-

- Other Special Substrates

-

1. Hot-Dip Galvanized Substrate

Hot-dip galvanizing is a commonly used metal surface corrosion protection method, where a layer of zinc-iron alloy is formed on the surface of steel products to provide protection.

Design Basis ISO12944-5:2017 Protective Paint Systems for Steel Structures Against Corrosion Environment C5 Very High; External: High humidity and harsh weather in industrial areas and coastal areas with high salinity. Design Lifespan VH Ultra Long-term Surface Treatment ISO 8501-1 St2: The surface of steel should be free from visible grease and dirt, and there should be no loosely attached oxide scale, rust, or paint layers. Coating Area Hot-dip galvanized substrates for embedded parts, guardrails, utility poles Coating Paint Type Paint Name Color Compatible Thinner A:B Ratio Film Thickness μm First Coat DreamCover Galvanizing Special Primer DreamCover 221 Light Grey, Semi-Gloss Epoxy Thinner DreamThinner 17 25:5 280 Second Coat DreamDur Acrylic Polyurethane Finish Paint DreamDur 550 Custom color matching for both national and international standards Polyurethane Thinner DreamThinner 10 21.4:3.6 80 Total 360 2. Stainless Steel Substrate

Stainless steel itself has good corrosion resistance, but in some cases, additional protective measures are needed to increase its durability and aesthetics.

Design Basis ISO12944-5:2017 Protective Paint Systems for Steel Structures Against Corrosion Environment C5 Very High; External: High humidity and harsh weather in industrial areas and coastal areas with high salinity. Design Lifespan VH Ultra Long-term Surface Treatment ISO 8501-1 St2: The surface of steel should be free from visible grease and dirt, and there should be no loosely attached oxide scale, rust, or paint layers. Coating Area Stainless steel embedded parts, guardrails, utility poles Coating Paint Type Paint Name Color Compatible Thinner A:B Ratio Film Thickness μm First Coat DreamCover Stainless Steel Special Primer DreamCover 221 Light Grey, Semi-Gloss Epoxy Thinner DreamThinner 17 25:5 280 Second Coat DreamDur Acrylic Polyurethane Finish Paint DreamDur 550 Custom color matching for both national and international standards Polyurethane Thinner DreamThinner 10 21.4:3.6 80 Total 360

-

- Bridge Maintenance: Failure Analysis / Basis / Coating Selection / Construction

-

I. Failure Analysis of Anti-Corrosion Coatings

The failure of anti-corrosion coatings refers to the degradation of various physical and chemical properties of the coating after long-term exposure to a corrosive environment, resulting in the loss of its original performance and partial or complete loss of protection for the bridge substrate.

The failure of bridge anti-corrosion coatings can be mainly divided into two categories: organic coating failure and metal coating failure.

1. Failure Analysis of Organic Coatings

The main cause of failure is the erosion of the coating by chemical substances, or the long-term effects of external environmental factors such as ultraviolet rays, hot and cold rain, and the swelling and diffusion of corrosive media leading to damage to the coating.

2. Failure Analysis of Metal Coatings

For metal coatings such as hot-dip zinc, hot-dip aluminum, hot-dip galvanizing, and zinc-rich coatings with metallic characteristics, they rely on the cathodic protection effect of zinc or aluminum during use, sacrificing themselves to protect the steel substrate. The failure form of metal coatings is uniform chemical or electrochemical corrosion. The corrosion life of the coating can be determined by the corrosion rate obtained from experiments, and the service life of the metal coating can be calculated based on the thickness of the coating. The corrosion failure of zinc-rich coatings combines the characteristics of both organic and metal coatings. On one hand, zinc-rich coatings provide cathodic protection to steel; on the other hand, the failure of the organic coating may cause the zinc particles to lose adhesion or fall off. Therefore, the service life of the zinc-rich coating depends on which of these two factors is dominant.

3. Failure of Composite Coatings

Modern bridge anti-corrosion systems are protective coatings combining metal and organic coatings. The outer organic coating can effectively block corrosive factors from attacking the metal coating and steel. The failure of composite coatings starts with the failure of the outer organic coating, most commonly as powdering or peeling. Due to the damage to the organic coating, corrosive factors can infiltrate the surface, causing the metal coating to fail. The accumulation of corrosion products can also reduce the adhesion of the organic coating.

II. Basis for Maintenance Coating

Due to the corrosion failure of anti-corrosion coatings, it is necessary to update and maintain the original anti-corrosion coating within a certain period to ensure the safety and durability of the bridge. But what is the basis for updating and maintaining? In simple terms, how do we judge the degree of failure of the original bridge coating—whether it is partial or complete? Under the premise of ensuring more economical and reasonable solutions, when is it absolutely necessary to update and maintain the bridge?

GB/T 1766-1995 "Color Paints and Varnishes—Method for Rating the Aging of Coatings" (referencing ISO 4628/1-5-1982) provides detailed evaluation methods. By assessing the blistering, rusting, cracking, and peeling of organic coatings, it grades the degree of corrosion failure, providing a simple and clear basis for relevant management and maintenance departments to develop maintenance plans.

According to the above standard rating, it is generally considered that when the comprehensive grade of organic coating failure reaches 3 (S3) or 4 (S4), the coating should be updated and maintained as soon as possible.

It is necessary to clarify the "rusting" item listed in the standard. Rusting occurs due to improper surface treatment of the substrate, insufficient coating thickness, or improper application, with existing penetrations. When rusting occurs, it indicates that the coating has completely lost its protective function in the affected area, which also impacts the overall anti-corrosion performance of the organic coating. The accumulation of corrosion products at the rusting spots can accelerate the blistering, peeling, and aging failure of surrounding coatings. According to anti-corrosion technology, when the rusted area of the coating reaches grade 3 (equivalent to Ri 3 in ISO 4628/3 or Re 3 in European standards), the coating should undergo maintenance. Therefore, for bridge structures, when the topcoat exhibits powdering above grade 3 and the thickness of the powdering is greater than 50% of the initial thickness, or if required by appearance, the surface should be thoroughly cleaned, and the compatible topcoat should be applied (1-2 layers). If the coating experiences cracking at grades 2-3, peeling at grades 2-3, or blistering at grades 2-3, but the primer is intact, appropriate intermediate and topcoats should be applied. When the coating shows rusting from Ri2 to Ri3, the surface should be thoroughly cleaned and the corresponding primer, intermediate coat, and topcoat applied.

III. Maintenance Coating Design and Construction

Developing a maintenance coating plan for a bridge is much more complex than developing a coating procedure for a new bridge. A systematic approach and specific tests are required to determine the condition of the original coating and the integrity of the overall structure. At the same time, careful consideration of the construction site's conditions, relevant environmental factors, and legal regulations concerning safety are necessary to create a targeted maintenance plan.

IV. Selection of Paint for Maintenance Coating

Before selecting maintenance coatings, a comprehensive analysis of the original coating must be carried out. This includes the adhesion condition of the original coating and the analysis of the original coating system. Simple on-site tests can give a rough idea of the original coating condition. For example, the cross-cut test (GB/T 9286-1988) can quickly assess the adhesion (between coatings, within the coating, or between the coating and substrate). The MEK (methyl ethyl ketone) wipe test can help determine whether the coating is physically dried, oxidatively cured, or chemically cured based on how the coating behaves when wiped. These tests provide rough results and can only serve as a reference. Accurate results require other methods or laboratory tests.

Additionally, the surface preparation requirements, site work conditions, painting equipment, and techniques must also be considered when selecting the maintenance coating.

Based on these tests and analyses, and by considering the compatibility between coatings and the expected service life of the coating design, the appropriate maintenance coatings can be selected.

V. Maintenance Coating Construction

Depending on the aging degree of the original coating, maintenance coating can involve partial repairs or complete renovation. For partial repairs, simple hand or power tools can be used to treat the surface of the affected areas, followed by roller, brush, or spray application for patching. For complete renovation, the original coating must be completely removed, and proper surface treatment (usually sandblasting) should be applied. The new anti-corrosion coating should be applied according to the construction requirements for a newly built bridge structure.

-

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience