Paper Mill Anti-Corrosion Solve

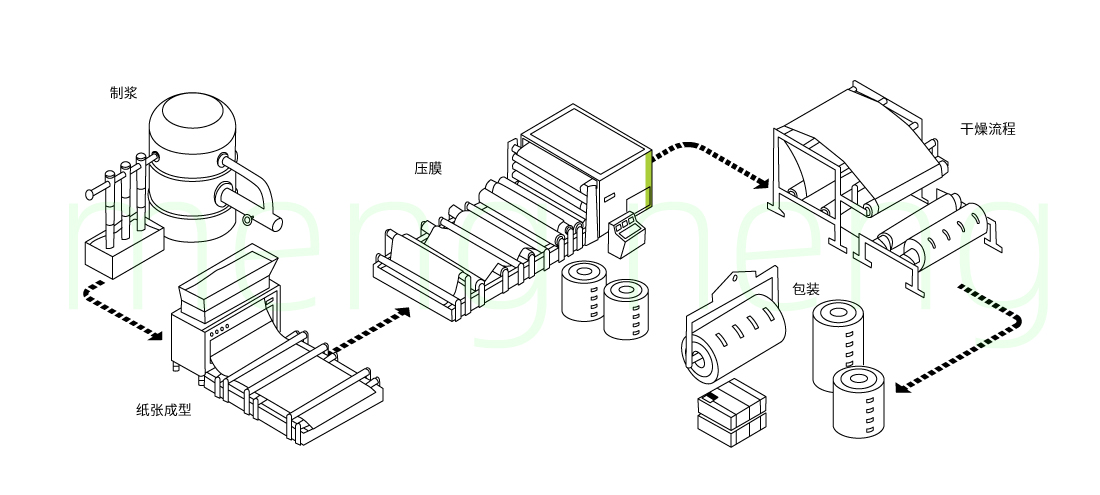

A paper mill is a factory that produces paper through a mechanized assembly line process. There are two types of papermaking: mechanical and handmade. Mechanical papermaking is done continuously on a papermaking machine, where pulp suitable for paper quality is diluted with water to a certain concentration. The pulp undergoes preliminary dewatering in the wire section of the machine, forming wet paper sheets, which are then pressed to remove water and dried to form paper. Handmade papermaking involves using a frame with bamboo mats, polyester mesh, or copper wire to collect the fibers suspended in water, forming a wet sheet of paper. After pressing to remove water, the paper is either air-dried or dried in an oven.

-

Corrosion Background

Corrosion Background -

Design Basis

Design Basis -

Pulp Pool

Pulp Pool -

Pulping Equipment

Pulping Equipment -

Paper Machine

Paper Machine -

Boiler Steel Structure

Boiler Steel Structure

-

- The corrosion background in paper mills

-

I. CORROSION BACKGROUND IN PAPER MILLS

Paper is an essential material in modern society for both daily life and production. It is not only a cultural necessity but also a vital industrial material. The paper industry is a significant sector of the national economy and is a traditional manufacturing industry.

In the paper industry in China, many mills use the alkali method for pulping, with key chemical raw materials including caustic soda, liquid chlorine, and aluminum sulfate. The management of equipment in paper mills is closely tied to corrosion prevention, which is a critical task.

As is well known, corrosion is a major issue in industrial production. In domestic industries, the economic losses caused by equipment corrosion have exceeded 10 billion yuan. In the chemical industry, it has become a critical problem. The consequences of equipment corrosion range from minor issues like leaks, environmental pollution, energy waste, quality degradation, and increased costs, to severe impacts such as personal safety risks, production shutdowns, and reduced profits.

Ensuring that manufacturing equipment is protected from corrosion has become a top priority.

-

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience