I. Gate Anti-Corrosion Plan

Corrosion not only affects the safe operation of the structure but also consumes a large amount of manpower, materials, and financial resources for anti-corrosion work. According to statistics from some sluice gate projects, the annual budget for gate anti-corrosion accounts for about half of the total annual maintenance costs. Moreover, a large workforce is required for tasks such as rust removal, painting, or spraying. Therefore, in order to effectively control the corrosion of steel and extend the service life of steel sluice gates, ensuring the integrity and safety of water conservancy and hydropower projects, the long-term anti-corrosion of steel sluice gates has attracted widespread attention.

In water conservancy and hydropower projects, steel sluice gates and steel structures are sometimes submerged in various water qualities (seawater, freshwater, industrial wastewater, etc.); sometimes due to water level changes or frequent opening and closing, they are exposed to a dry-wet alternating environment; some may also be subjected to the impact of high-speed water flow, abrasion by sand, floating objects, and ice; parts of the structure above the water surface may be affected by the humid atmosphere and splashing water mist; structures working in the atmosphere are exposed to sunlight and air. Given the harsh working environment and multiple influencing factors, it is necessary to analyze the corrosion factors.

The factors contributing to the corrosion of sluice gates are:

1) Climate factors: The upper part of the sluice gate above the water is easily affected by sunlight, rain, and humid atmosphere, leading to corrosion.

2) Surface condition of steel structures: Rough surfaces, mechanical damage, holes, welding defects, and gaps have a significant impact on corrosion.

3) Stress and deformation: The greater the stress and deformation, the more severe the corrosion.

4) Water quality: Freshwater has a low salt content, and the corrosion of the gate depends on its chemical composition and pollution. Seawater has a high salt content, good conductivity, and contains large amounts of chloride ions, which greatly increase the corrosion of steel. Gates in seawater experience more serious corrosion.

5) Water flow speed: The gate is subjected to high-speed impact from water flow and sand particles, causing erosive wear on the metal surface. Meanwhile, the flow of water enhances polarization, which easily washes away corrosion products from the structure surface, accelerating the corrosion process. Therefore, gates that are frequently opened to discharge water corrode more than those that remain closed for long periods.

Table 1: Anti-Corrosion Plan for Steel Sluice Gates Using Hot-Dip Galvanizing + Paint

The hot-dip galvanizing process is an anti-corrosion construction technology for sluice gates. It involves spraying zinc that is melted at high temperatures into particles and spraying it onto the surface of the sluice gate to form a zinc-iron alloy layer, achieving corrosion resistance and rust prevention. Specifically, the hot-dip galvanizing process includes surface preparation (such as sandblasting for rust removal), hot-dip coating (using a flame wire spray gun to apply zinc, with a coating thickness of approximately 160 μm), and post-treatment (combining brush coating and spray painting, with specific requirements for the thickness of primer and topcoat). This process not only improves the corrosion resistance of the gate but also extends its service life.

|

Design Basis

|

ISO 12944-5:2017 Protective Paint Systems for Steel Structures Against Corrosion

|

|

Environment

|

Im1; Freshwater: Facilities installed on rivers, hydropower stations

|

|

Design Life

|

H Long-term

|

|

Surface Treatment

|

ISO 8501-1 St2: Thorough hand and power tool rust removal. The steel surface should be free of visible grease, dirt, and any loosely adhered oxide scale, rust, and paint layers.

|

|

Coating Area

|

Metal sluice gates with hot-dip galvanizing

|

Table 2: Anti-Corrosion Plan for Steel Sluice Gates Using Cold Spray Zinc

The advantages of using cold spray zinc instead of hot-dip galvanizing are mainly reflected in the following aspects: First, cold spray zinc is simpler and more efficient in application, as it can be applied using brushing, rolling, or spraying methods, making it more flexible and easier to operate compared to the complex hot-dip galvanizing process. Second, cold spray zinc is more environmentally friendly, as it generates fewer pollutants and has a lower impact on the environment and human health, in line with national environmental policies. Furthermore, cold spray zinc consumes less energy, as it does not require maintaining a high-temperature environment like hot-dip galvanizing. Additionally, cold spray zinc coatings have better durability, longer maintenance cycles, and reduced long-term maintenance costs. Lastly, when cold spray zinc coatings suffer local damage, they are easier to repair by directly coating the damaged area, whereas hot-dip galvanized coatings often require a complex pre-treatment process for repair.

|

Design Basis

|

ISO 12944-5:2017 Protective Paint Systems for Steel Structures Against Corrosion

|

|

Environment

|

Im1; Freshwater: Facilities installed on rivers, hydropower stations

|

|

Design Life

|

H Long-term

|

|

Surface Treatment

|

ISO 8501-1 Sa2.5: Very thorough abrasive blasting or shot blasting for rust removal. The steel surface should be free of visible grease, dirt, oxide scale, rust, and paint coatings.

|

|

Coating Area

|

Steel sluice gates

|

Table 3: Graphene Coating Anti-corrosion Solution for Steel Sluice Gates

The application of graphene coatings to sluice gates offers significant advantages: its high specific surface area and conductivity improve anti-corrosion performance, enhance substrate adhesion, reduce coating thickness while increasing wear resistance. The mechanical properties of graphene improve the coating's impact resistance and flexibility, adapting to environmental changes and reducing cracking. It is environmentally friendly and non-toxic, improving sluice gate efficiency, reducing maintenance costs, and making it an ideal choice that combines both environmental and performance benefits.

|

Design Basis

|

ISO12944-5:2017 Protective Paint Systems for Steel Structures against Corrosion

|

|

Environment

|

Im1; Freshwater: Facilities installed on rivers, Hydropower plants

|

|

Design Life

|

H Long-term

|

|

Surface Treatment

|

ISO 8501-1 Sa2.5: Very thorough blast or abrasive rust removal. Steel surface free from visible grease, dirt, scale, rust, paint coating, or other contaminants. Any remaining traces should only be minor pinpoint or streak marks.

|

|

Coating Location

|

Steel Sluice Gate

|

Corrosion Background

Corrosion Background  Design Basis

Design Basis  Gates

Gates  Hoisting Machines

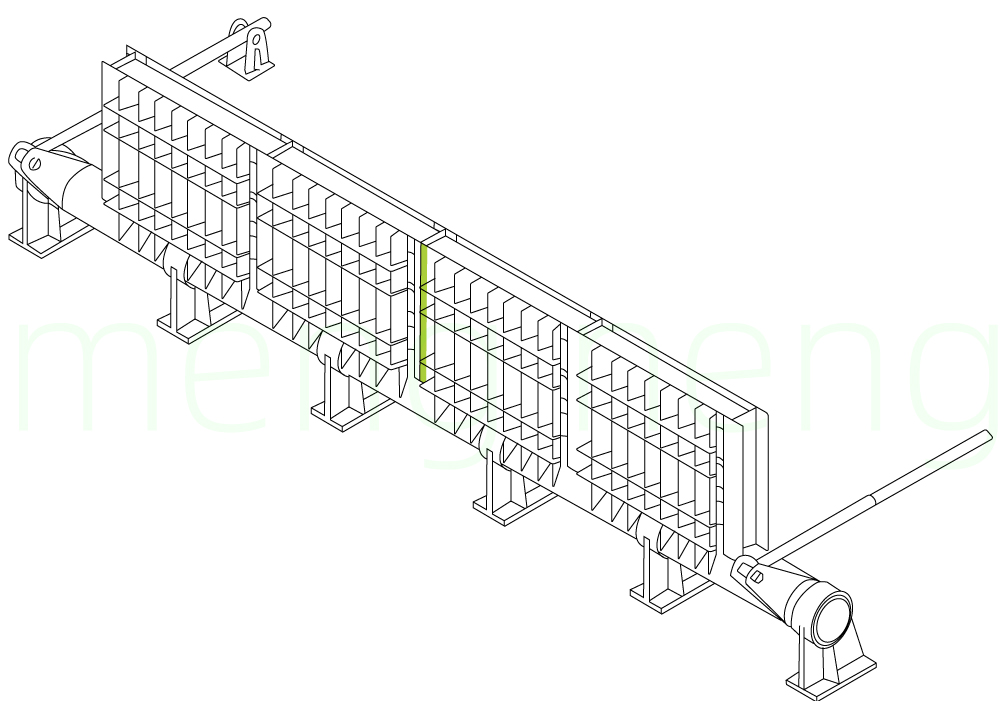

Hoisting Machines  Trash Rakes

Trash Rakes  Winches

Winches