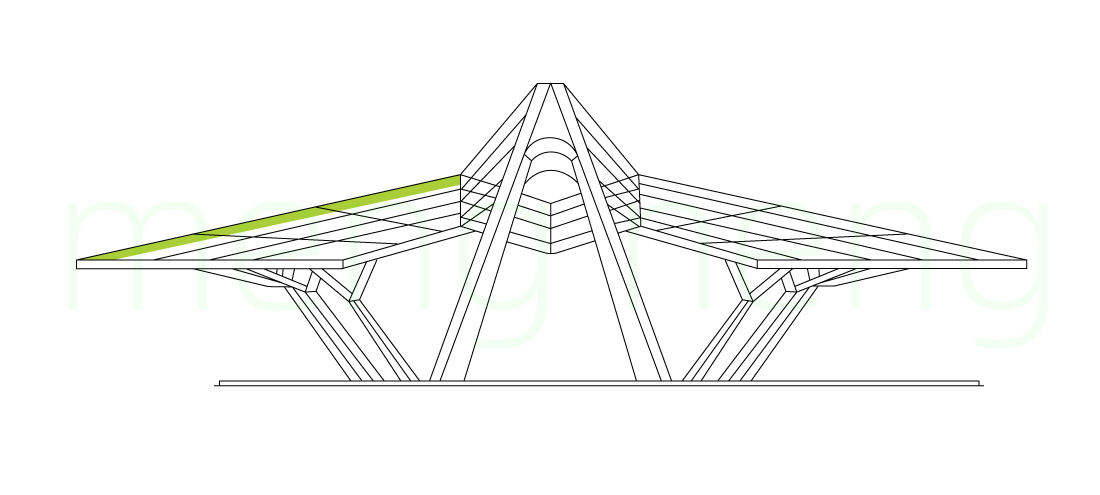

I. New Anti-Corrosion Scheme for Airport Terminal

In recent years, urban construction in China has developed rapidly, and many tall civil and industrial buildings use steel structures, which effectively utilize the advantages of high strength, light weight, good seismic performance, high industrialization, and short construction periods. However, during the construction and use of steel structures, the corrosion of steel is a serious issue that significantly affects the durability of the structures. Steel corrosion can be divided into two types. One is chemical corrosion, which occurs when the surface of the steel reacts chemically with the surrounding environment, and the degree of corrosion increases with time and temperature. The other is electrochemical corrosion, which occurs when oxidation-reduction reactions happen between steel and its surrounding environment during storage and use. Steel structure corrosion is not just rusting of the material, but a complex chemical-physical process, ultimately impacting the structural reliability and economic indicators.

Table 1: Anti-Corrosion Scheme for Airport Terminal

For the anti-corrosion engineering of the steel structures in the airport terminal, it is recommended to use a combination of graphene epoxy zinc-rich primer, epoxy micaceous iron oxide intermediate paint, and fluorocarbon topcoat. This combination can effectively provide corrosion protection while offering good weather resistance and aesthetic appeal. During construction, the steel surface should be sandblasted to Sa2.5 standard to enhance paint adhesion. These measures will ensure effective corrosion protection for the terminal's steel structures, extend their service life, and maintain the aesthetic appearance of the building.

|

Design Basis

|

ISO12944-5:2017 Protective coatings for steel structures against corrosion

|

|

Environmental Conditions

|

C3 Medium; External: Urban and industrial atmosphere, moderate sulfur dioxide pollution, and low salinity coastal areas

|

|

Design Life

|

VH Ultra Long Term

|

|

Surface Treatment

|

ISO 8501-1 Sa2.5: Very thorough sandblasting or abrasive cleaning. The steel surface should be free from visible oil, dirt, scale, rust, old coatings, and other contaminants. Any remaining traces should be light, localized spots or streaks.

|

|

Coating Locations

|

Airport Terminal

|

II. Anti-corrosion Solution for Renovation of Airport Terminal

When renovating the airport terminal, the anti-corrosion coating solution needs to consider the following issues: First, the selection of coatings should be based on the terminal environment. For coastal areas, coatings resistant to salt mist corrosion are required. Secondly, surface treatment is crucial, and it must be thoroughly cleaned and achieve the appropriate roughness to enhance paint adhesion. The temperature and humidity of the construction environment will also affect the coating performance, so construction should be carried out under suitable conditions. Fire resistance is a key requirement for public buildings, and the coating must comply with fire safety regulations. Strict quality control during construction is essential to ensure an even and flawless coating. Regular inspections and maintenance are necessary to extend the service life. The selection of environmentally friendly coatings can reduce VOC emissions, in line with green building standards. The coating system should be reasonable, with primer, intermediate, and topcoats working together to ensure anti-corrosion effectiveness. Finally, the paint quantity should be calculated reasonably, considering the theoretical spreading rate and actual loss, to reduce waste. By considering these factors, effective corrosion protection for the terminal steel structure can be ensured, enhancing durability and safety.

Table 2: Anti-corrosion Solution for Renovation of Airport Terminal

|

Design Basis

|

ISO12944-5:2017 Protective Coating Systems for Steel Structures Against Corrosion

|

|

Environment

|

C3 Medium; External: Urban and industrial atmosphere, moderate sulfur dioxide pollution, and low salinity coastal areas

|

|

Design Life

|

VH Ultra-long

|

|

Surface Treatment

|

ISO 8501-1 Sa2.5: Thorough blasting or abrasive cleaning. The steel surface should be free of visible grease, dirt, scale, rust, paint coatings, or other contaminants. Any residual traces should be minor, localized, or linear discolorations.

|

|

Coating Location

|

Airport Terminal

|

|

Coating

|

Coating Type

|

Coating Name

|

Color

|

Thinner

|

A:B Ratio

|

Film Thickness

|

|

First Coat

|

DreamCover

|

Graphene Low Surface Treatment Primer DreamCover 220 Gns

|

Grey

|

Special Thinner DreamThinner 17 Gns

|

25:5

|

200

|

|

Second Coat

|

DreamCover

|

Fireproof Coating (3 hours fire resistance)

|

White

|

Special Thinner DreamThinner 17 Gns

|

25

|

3000

|

|

Third Coat

|

DreamDur

|

Fluorocarbon Topcoat DreamDur 22F

|

Customizable Color

|

Special Thinner DreamThinner X

|

22.73:2.27

|

80

|

|

Total

|

|

3280

|

Corrosion Background

Corrosion Background  Design Basis

Design Basis  Sports Venues

Sports Venues  High-speed Rail Stations

High-speed Rail Stations  Airport Terminals

Airport Terminals  Landscape Towers

Landscape Towers  Urban Integrated Pipe Gallery

Urban Integrated Pipe Gallery