3rd-Gen Coatings

- Detail View

- Thumbnail View

-

-

- Cold Spray ZincDreamZinc Cold-spray zinc DreamZinc 96

-

The cold spray zinc product is a new type of heavy-duty anti-corrosion material composed of self-made special resins, high-purity zinc powder, environmentally friendly solvents, and additives. It complies with the performance standard HG/T 5573-2019 "Graphene Zinc Powder Coating." The product is well-matched and stable, with high adhesion and high construction tolerance. The coating exhibits excellent anti-rust properties and can replace traditional coating materials such as epoxy zinc-rich coatings in C2, C3, and C4 environments.

- Apps:

- Steel MillPower PlantBridge

-

-

-

- Cold Spray ZincDreamCover Cold-spray zinc sealer DreamCover 167

-

Cold spray zinc sealer is a two-component polyamide-cured polymer material. It is specifically designed for sealing cold spray zinc, galvanized parts, and thermal spray zinc coatings. It is used as an intermediate coating in atmospheric environments.

- Apps:

- Steel MillPower PlantBridge

-

-

-

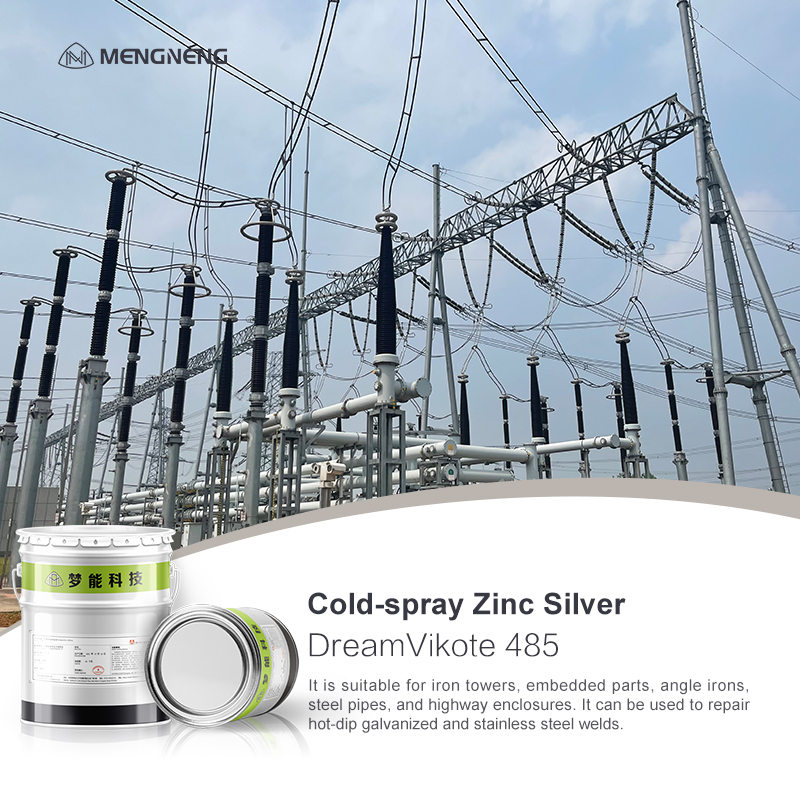

- Cold Spray ZincDreamVikote Cold-spray zinc silver DreamVikote 485

-

Cold spray silver products mainly replace electroplated zinc. This product is primarily composed of silver powder, solvents, and additives. It features corrosion resistance, aesthetic appearance, reflectivity, fast drying, strong adhesion, and scratch resistance.

- Apps:

- Steel MillPower PlantBridge

-

-

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience