Inorganic zinc silicate workshop primer DreamZinc 08 ( 2nd-Gen Coatings )

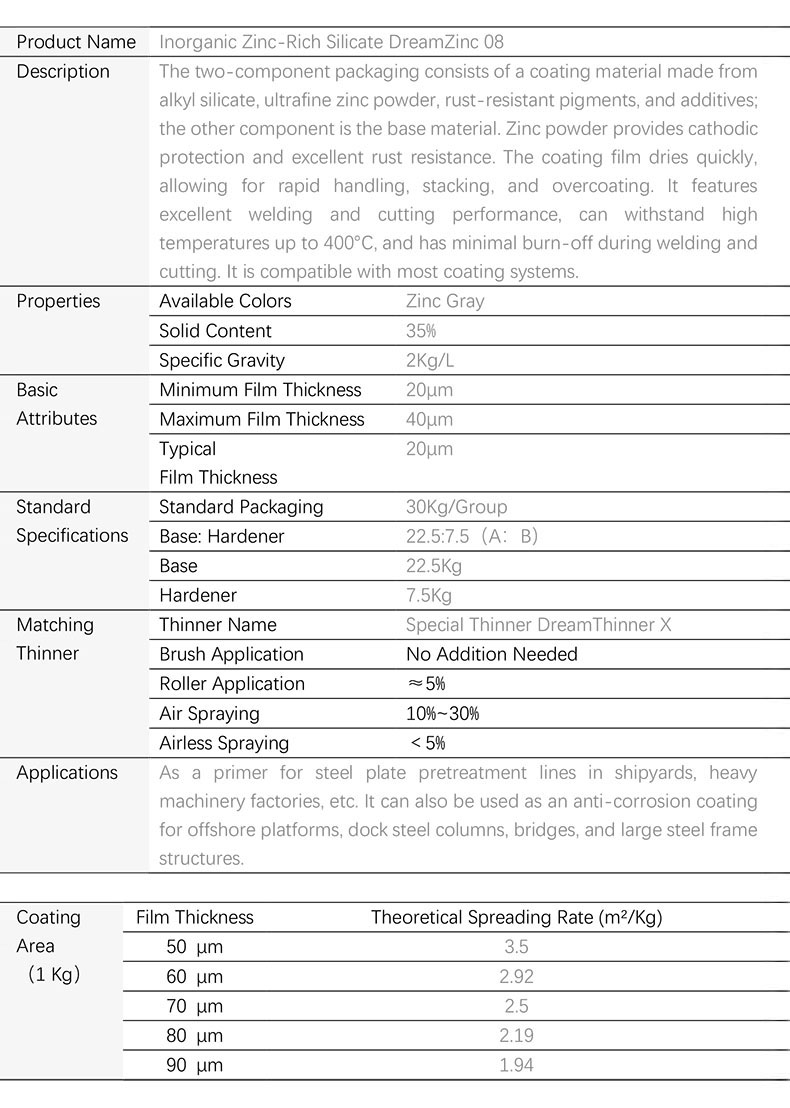

The two-component packaging consists of a coating material made from alkyl silicate, ultrafine zinc powder, rust-resistant pigments, and additives; the other component is the base material. Zinc powder provides cathodic protection and excellent rust resistance. The coating film dries quickly, allowing for rapid handling, stacking, and overcoating. It features excellent welding and cutting performance, can withstand high temperatures up to 400°C, and has minimal burn-off during welding and cutting. It is compatible with most coating systems.

- Use

- As a primer for steel plate pretreatment lines in shipyards, heavy machinery factories, etc. It can also be used as an anti-corrosion coating for offshore platforms, dock steel columns, bridges, and large steel frame structures.

- ALBUM

- PARAMETERS

- MATCHING

-

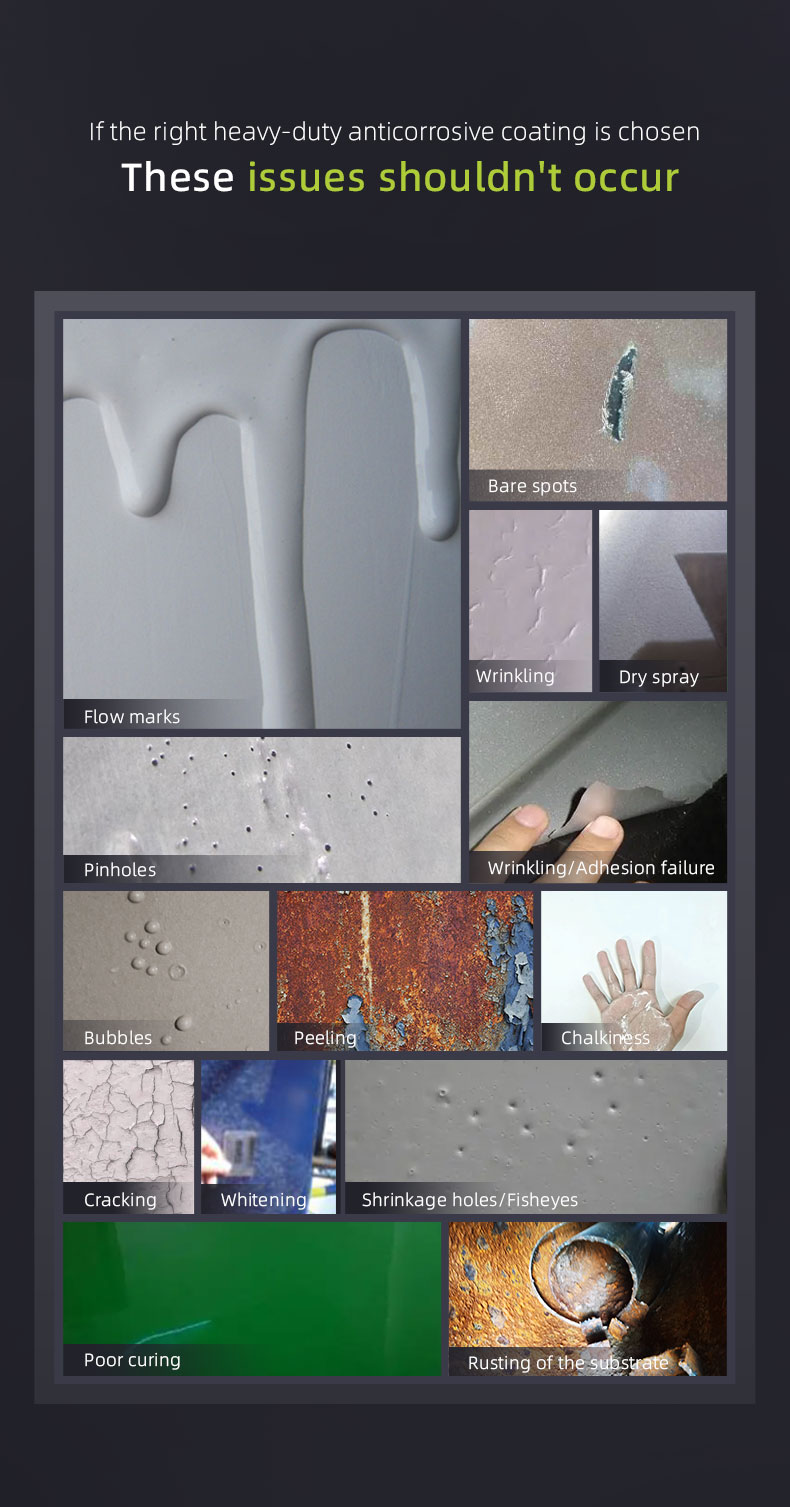

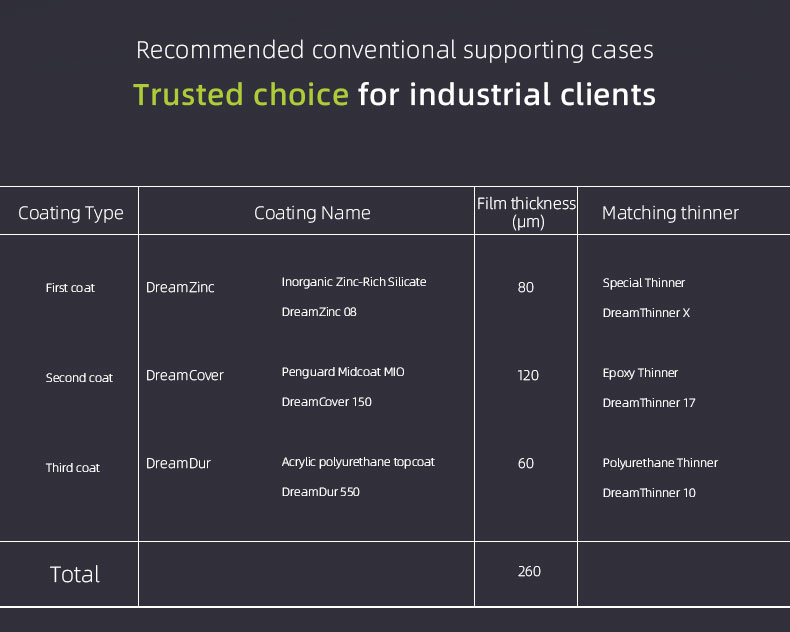

How to Select the Right Coating Type?

We don't know where to start.

-

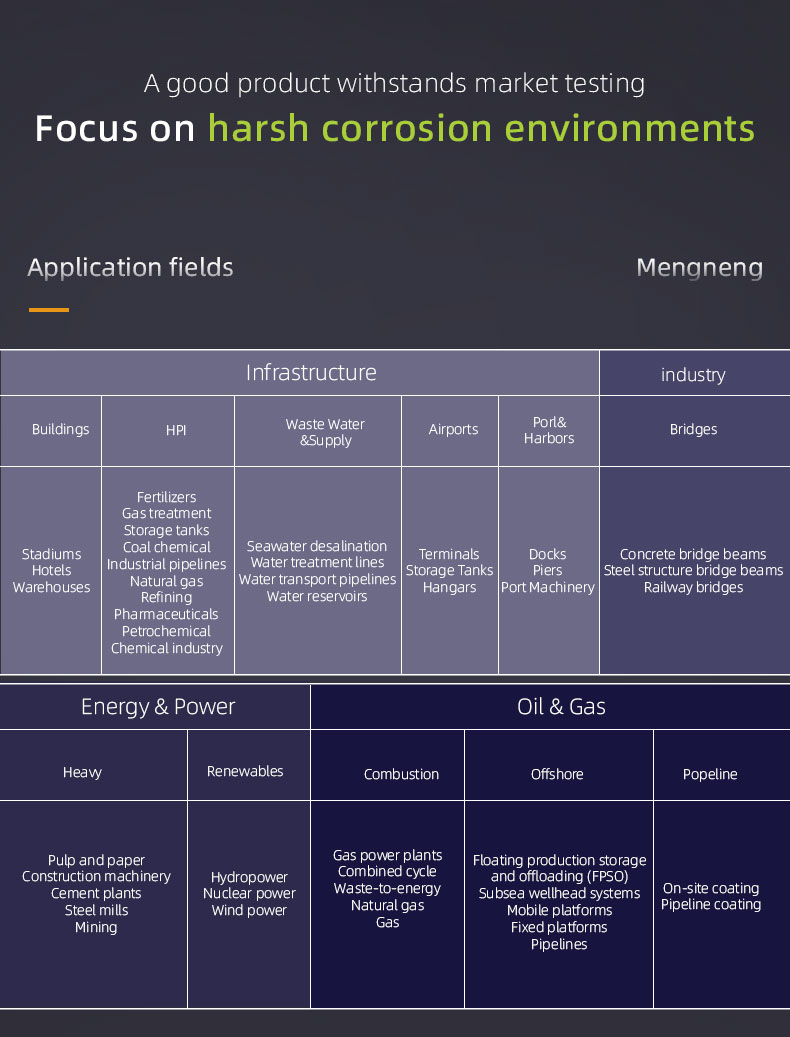

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience