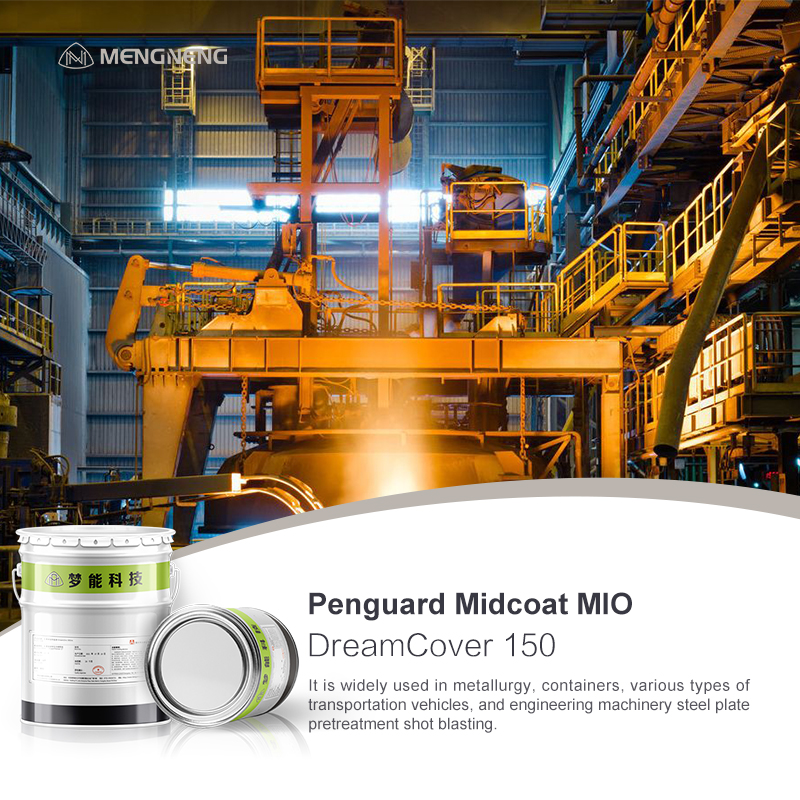

Epoxy micaceous iron oxide intermediate coating DreamCover 150 ( 2nd-Gen Coatings )

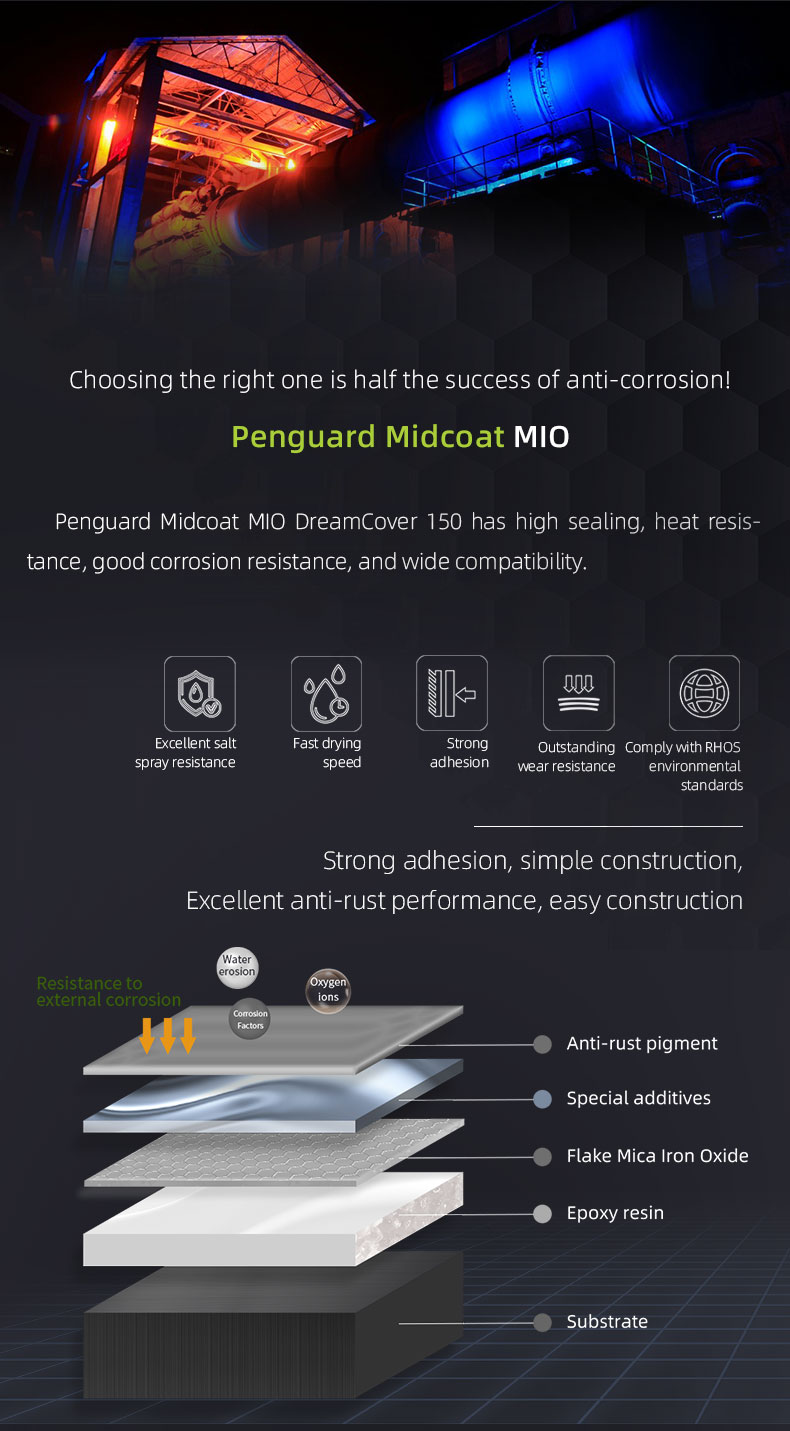

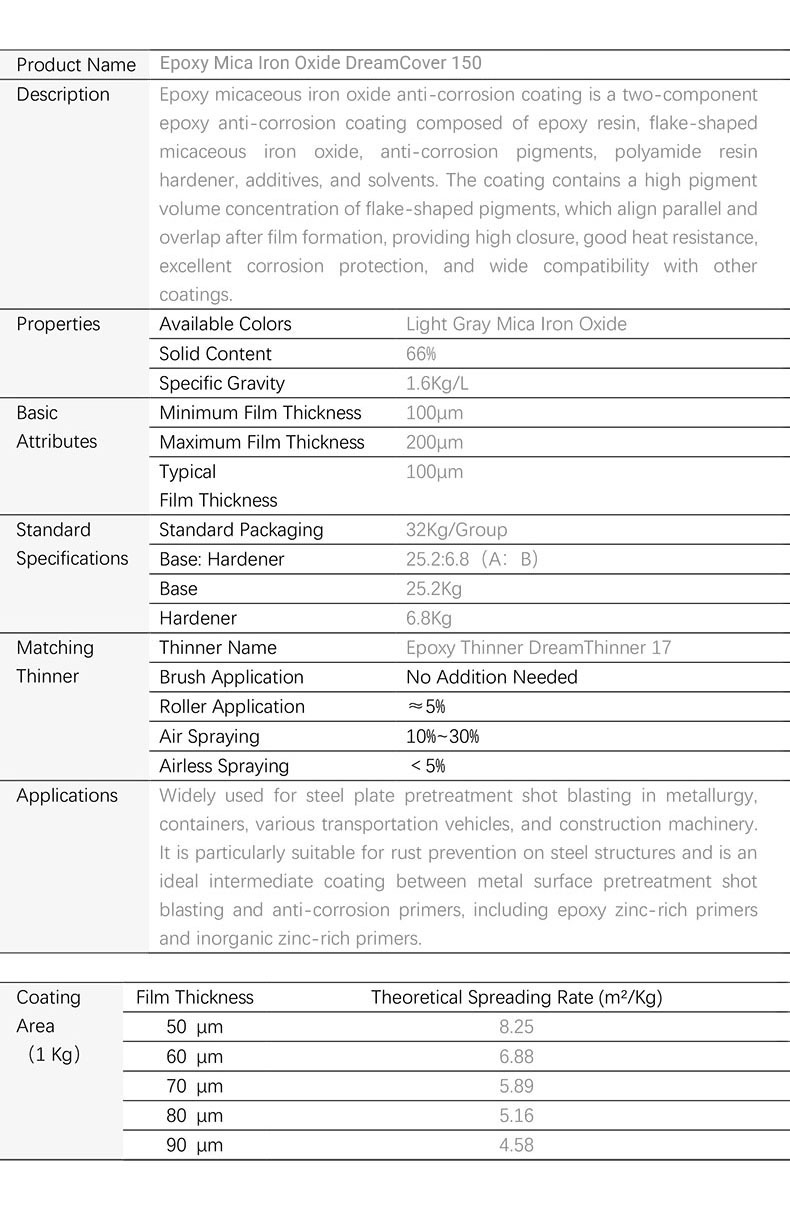

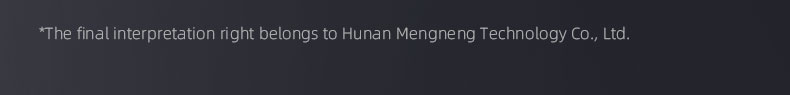

Epoxy micaceous iron oxide anti-corrosion coating is a two-component epoxy anti-corrosion coating composed of epoxy resin, flake-shaped micaceous iron oxide, anti-corrosion pigments, polyamide resin hardener, additives, and solvents. The coating contains a high pigment volume concentration of flake-shaped pigments, which align parallel and overlap after film formation, providing high closure, good heat resistance, excellent corrosion protection, and wide compatibility with other coatings.

- Use

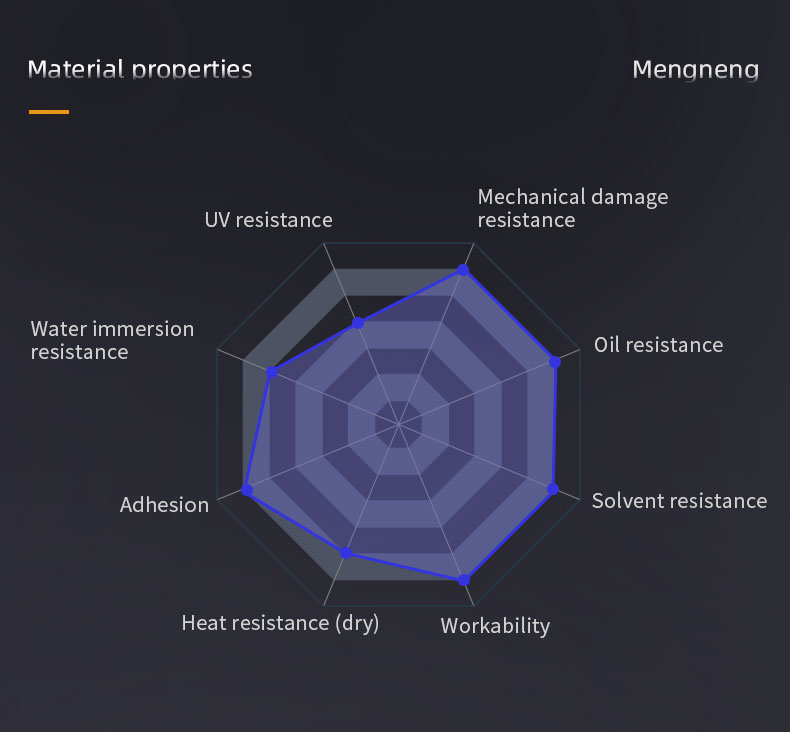

- Widely used for steel plate pretreatment shot blasting in metallurgy, containers, various transportation vehicles, and construction machinery. It is particularly suitable for rust prevention on steel structures and is an ideal intermediate coating between metal surface pretreatment shot blasting and anti-corrosion primers, including epoxy zinc-rich primers and inorganic zinc-rich primers.

- ALBUM

- PARAMETERS

- MATCHING

-

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience