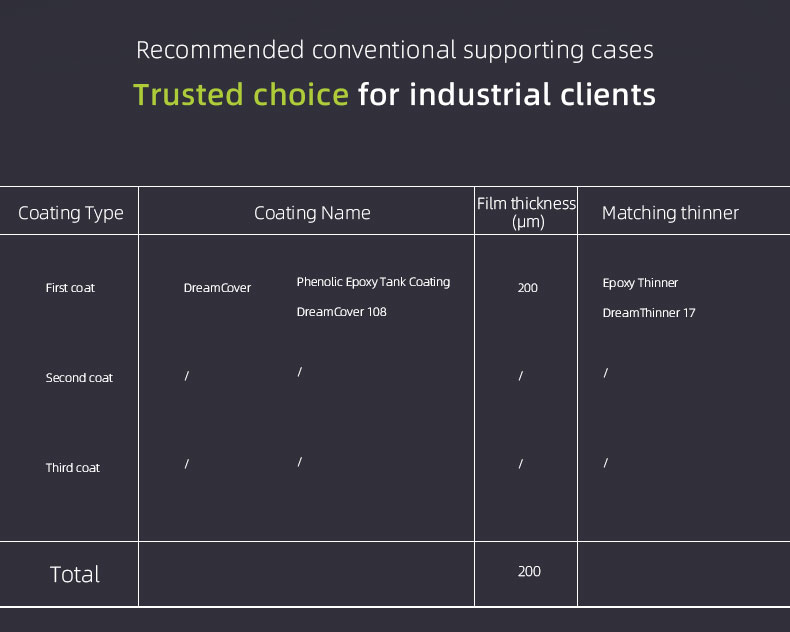

Phenolic epoxy tank coating DreamCover 108 ( 2nd-Gen Coatings )

High Performance Coatings

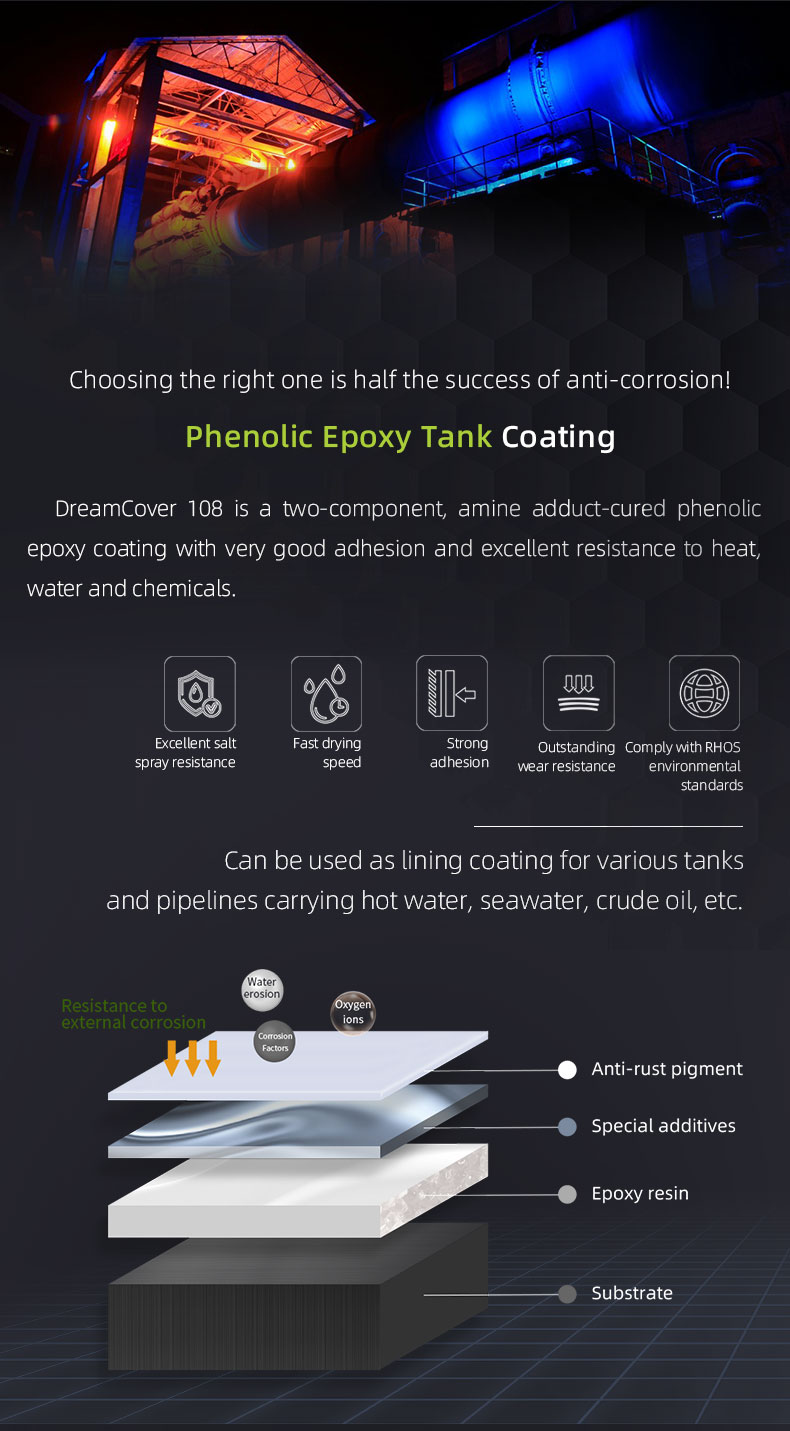

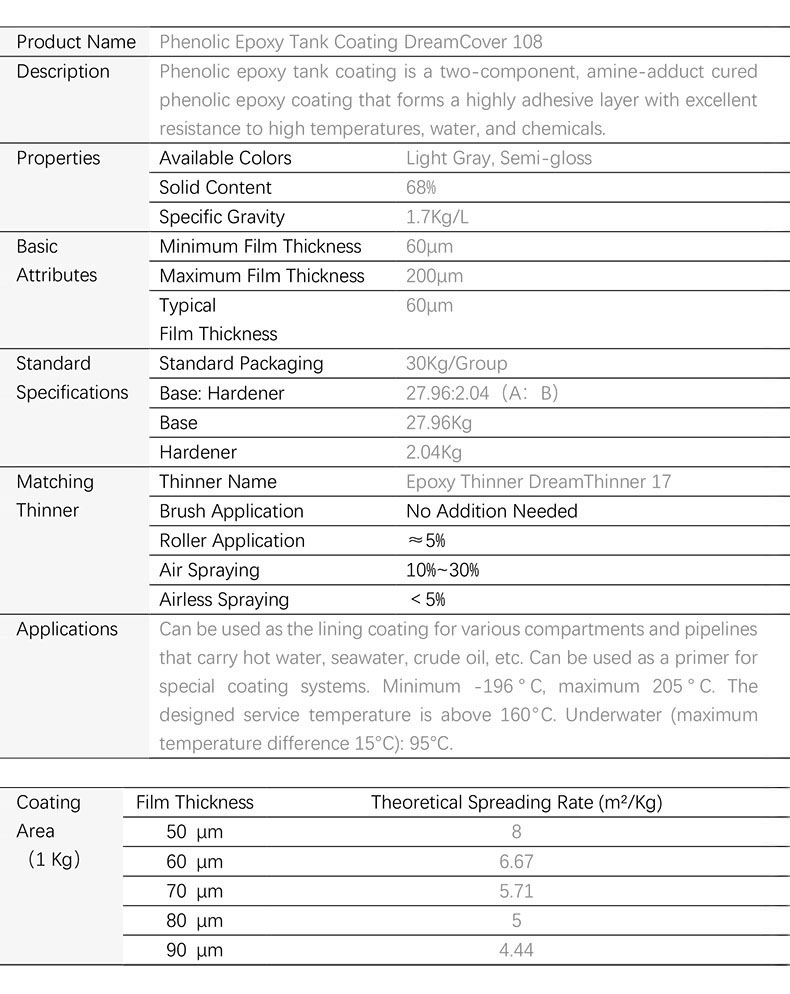

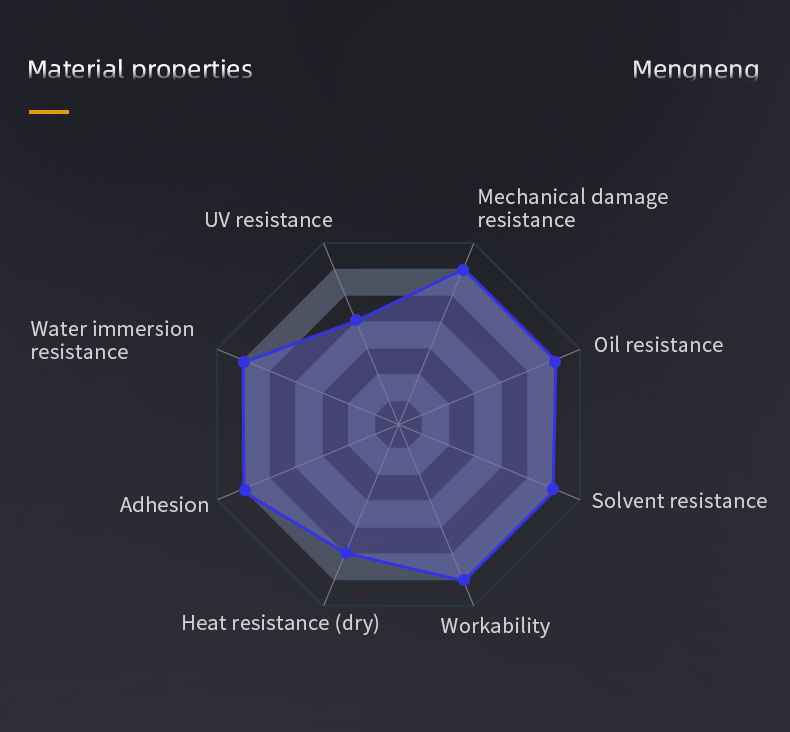

Phenolic epoxy tank coating is a two-component, amine-adduct cured phenolic epoxy coating that forms a highly adhesive layer with excellent resistance to high temperatures, water, and chemicals.

- Use

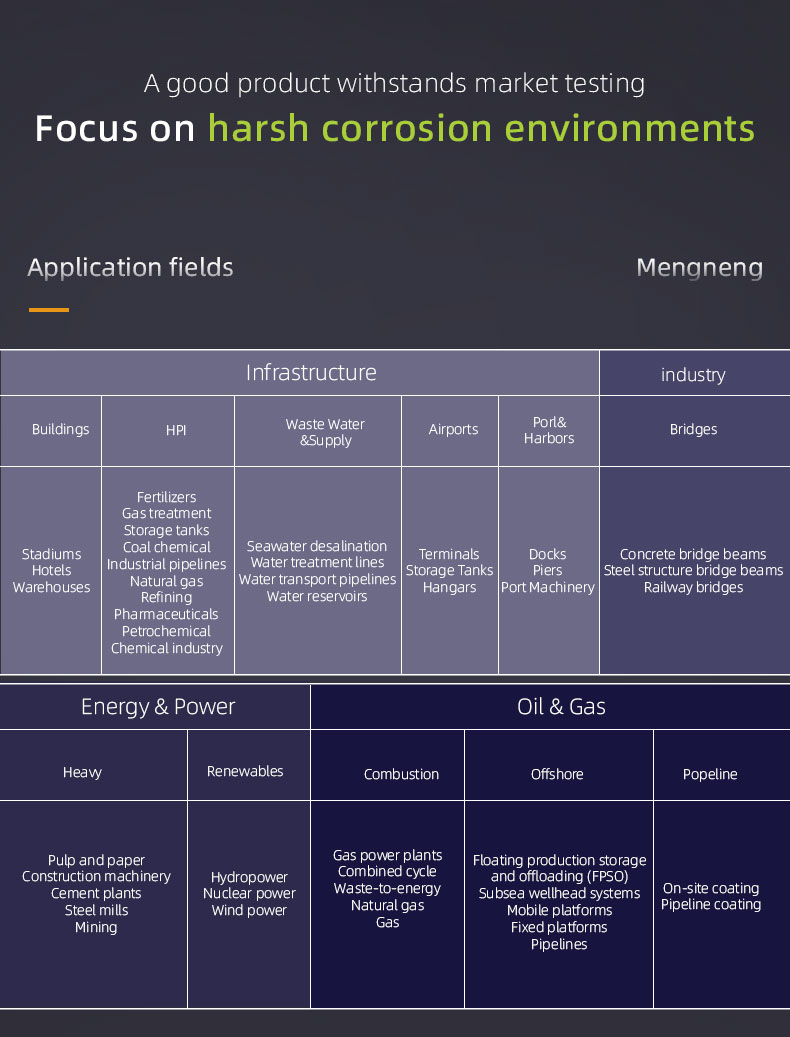

- Can be used as the lining coating for various compartments and pipelines that carry hot water, seawater, crude oil, etc. Can be used as a primer for special coating systems. Minimum -196°C, maximum 205°C. The designed service temperature is above 160°C. Underwater (maximum temperature difference 15°C): 95°C.

- ALBUM

- PARAMETERS

- MATCHING

-

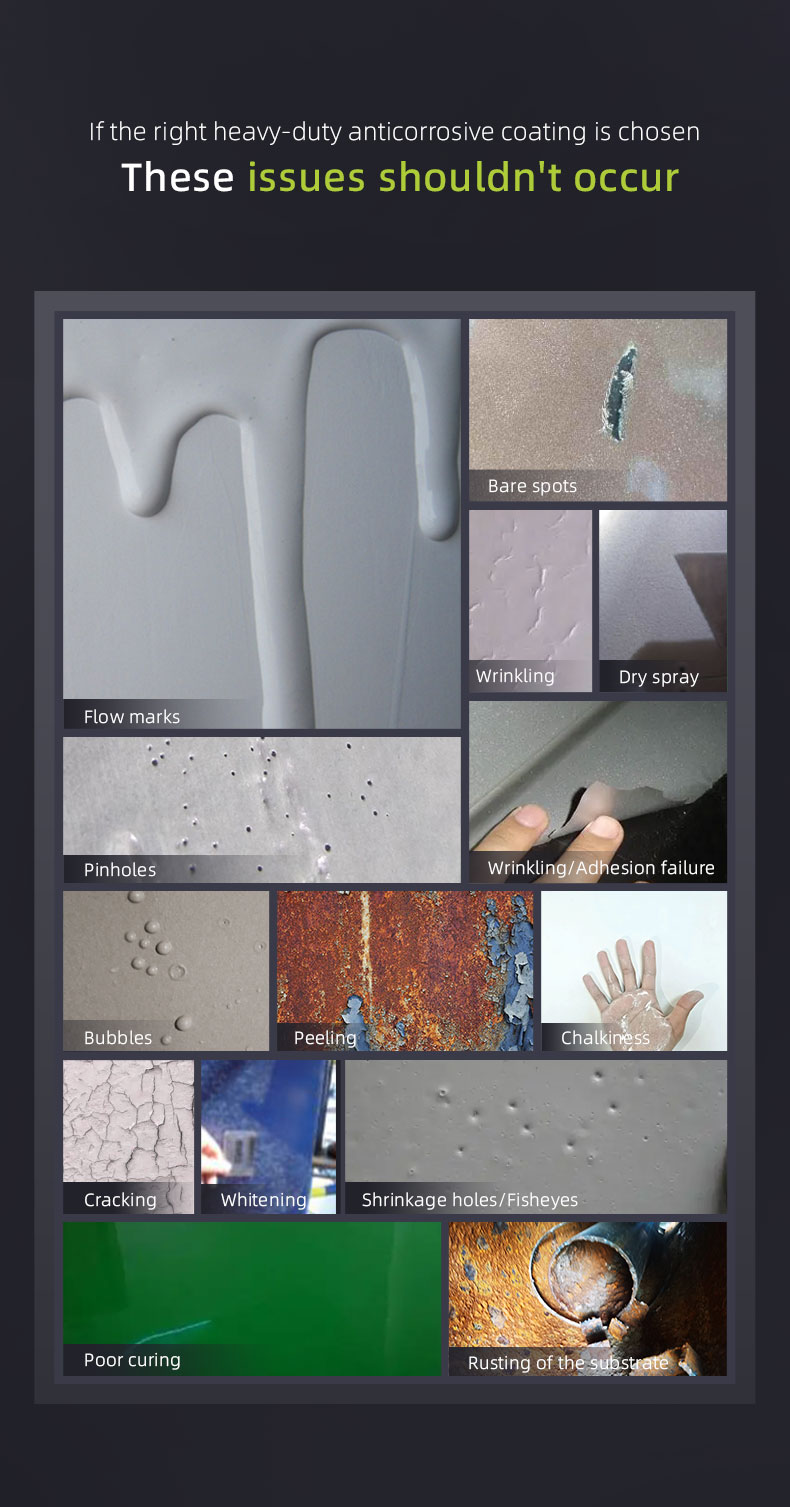

How to Select the Right Coating Type?

We don't know where to start.

-

ISO 12944 is a standard developed for corrosion protection of steel structures by paints, determining the corrosive environment, anti-corrosion life, paint matching, and film thickness.

Choose

-

How to Solve Industry with Coatings?

Corrosion factors are numerous and varied.

-

We serve municipal engineering, chemical industry, power plants, steel structure factories, and wastewater treatment plants, with numerous successful cases and experience.

Experience